Petroleum Engineering

Contents

Petroleum Engineering

Petroleum Engineering is a process of maximizing oil and gas production.

The oil and gas companies apply Petroleum Engineering in gas and oilfields to maximize wells and reservoirs production by identifying and closing performance gaps by Gap Analysis.

Petroleum Engineering allows to produce gas and oil wells and reservoirs at their potential in a most economical way while achieving maximum recovery.

New Petroleum Engineering Workflow

- Assess the current gas for oilfield performance. What is the current oil and gas production? Get organized with the available oil and gas production data.

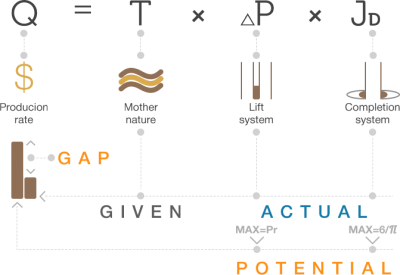

- Calculate the Production Potential and identify the performance gaps in a form of Enhancement List.

- Close the performance gaps by executing identified Enhancements.

- Track the benefits achieved with the Enhancement Tracking.

Such a workflow can be applied both on a well level and on a oilfield pattern level. The petroleum engineer task is to keep wells at potential and patterns balanced while management should be held accountable that the prescribed actions are implemented in a timely manner[1].

Routine execution of described Petroleum Engineering Workflow results in more production, improved recovery and increased earnings.

Petroleum Engineering Technology

- Darcy's law

- Nodal Analysis

- Artificial Lift, especially Electrical Submersible Pumps

- Hydraulic fracturing

- Waterflooding

Petroleum Engineering Technology allows achieving Production Potential, which is maximum drawdown in the Lift System and maximum well's productivity index in the Completion System.

Oil and Gas production optimization challenges

The ideal, of producing and recovering at potential, is rarely obtained in practice. Reasons for this vary from company to company, but more often than not, the reason is well potentials are not known and therefore not managed. Introducing petroleum engineering workflow of maximizing oil and gas production in such oil and gas companies will usually face a resistance in a form of excuses why not to increase production. Below are top 10.

Top 10 reasons why NOT to increase oil and gas production

- Can not produce below the bubble point: IPR curve reverses

- Pulling the chokes will make production decrease

- Water will break through sooner

- Facility is full

- We don't have big pumps

- It's on order but won't be here for at least 2 months

- FRACs go away

- Casing is too small

- Material balance does not work

- This physical law works good in the theory, but can not be applied to the real fields we have here.

More reasons are given here. Those challenges are not backed up with math and physics and can be overcome by petroleum engineering programs and courses held within the company.

Petroleum Engineering Career Advice

Advice on managing and being more successful with your Petroleum Engineering Career[1]. This is a useful career advice for for the student who is doing his petroleum engineering degree in a school, college, university or doing an internship. This is also helpful for the practicing engineer as a reference and a source for new ideas to make a difference on their petroleum engineering job and to increase salary.

- Calculate Potential and be a Performance Engineer

Performance is defined as the quality of results compared to potential. Therefore, for any endeavor you undertake, if you want to speak about its performance you must know its potential. Calculate the potential whenever possible and determine the performance gap by comparing actual results with potential[1].

- Stop Complaining about No Data

You should practice showing value added opportunities with the data that is available. Special or additional data is justified on an as needed basis. If more data is needed then show what opportunity is created and how a decision can be made by collecting the data[1].

- Focus on Opportunities and Execution

Look first for the "quick-hit" opportunities. Focus on action not studies. Organize the identified opportunities on a enhancement list, calculate potential and rank them based on performance gap. Make a plan to close the performance gaps based on the opportunities identified, execute the plan and track the results. Engineers who work on opportunities develop a trait of making quicker decisions and accelerating the tempo of the organization, which translated into better performance[1].

- Know-How or Technology what is most differential?

For the service companies its technology, for the oil companies its know-how. Work to develop individual know-how and expertise in your discipline. This is done by deliberately practicing your trade at ever increasing levels of difficulty. Push the limits of your knowledge and skills, routinely, and look for feedback from colleagues, management and professional societies[1].

Petroleum Engineering Job Description

Typical PE JD

petroleum engineering requirement