Difference between revisions of "Category: Enhancement List"

(→WHP and WOP) |

|||

| (48 intermediate revisions by the same user not shown) | |||

| Line 7: | Line 7: | ||

Routine execution of the identified [[Enhancement| Enhancements]] unlocks the pathway to [[Production Potential]] and results in more production, improved recovery and increased earnings. | Routine execution of the identified [[Enhancement| Enhancements]] unlocks the pathway to [[Production Potential]] and results in more production, improved recovery and increased earnings. | ||

| − | [[File:Enhancement List. | + | [[File:Enhancement List.jpeg| Enhancement List]] |

| + | |||

| + | <center>[[:Category:Enhancement List | Enhancement List]] at the [[:Category:E&P Portal | E&P Portal]]</center> | ||

==Workflow== | ==Workflow== | ||

| − | + | ===1. Current Performance=== | |

| + | [[:Category:Enhancement List | Enhancement List]] requires a lot of data been measured and processed and without an automated system a lot of manual work. | ||

| + | |||

| + | The minimum required data set is: | ||

| + | |||

| + | *[[Field]] | ||

| + | *[[Reservoirs]] and [[PVT]] | ||

| + | *[[Well]] | ||

| + | *Well Type (producer, injector, history of change) | ||

| + | *Well Operation Type (flowing, artificial list, history of change) | ||

| + | *[[Daily Measures | Well Daily Measures]] (specifically flowing rates, fluid levels, pressures) | ||

| + | *[[Deviation Survey]] | ||

| + | *[[Perforations]] | ||

| + | *kh & JD | ||

| + | *Well Downhole Equipment | ||

| + | *Well Design | ||

| + | |||

| + | ===2. Production Potential=== | ||

| − | ===WHP and WOP=== | + | [[Production Potential]] is calculated: |

| + | |||

| + | ====WHP and WOP==== | ||

* '''Wellhead Potential (WHP)''' - is the maximum rate that can be achieved with existing well equipment with no workover (Choke open, Speedup the ESP, etc). | * '''Wellhead Potential (WHP)''' - is the maximum rate that can be achieved with existing well equipment with no workover (Choke open, Speedup the ESP, etc). | ||

| + | |||

* '''Workover Potential (WOP)''' - is the maximum rate that can be achieved with workover. The assumption is that the current skin will be mitigated with better completion during the workover. And the largest tubing practical that will fit in the current well bore will be used. | * '''Workover Potential (WOP)''' - is the maximum rate that can be achieved with workover. The assumption is that the current skin will be mitigated with better completion during the workover. And the largest tubing practical that will fit in the current well bore will be used. | ||

| Line 32: | Line 54: | ||

<td>Gas</td> | <td>Gas</td> | ||

<td>Flowing</td> | <td>Flowing</td> | ||

| − | <td> Calculated with Nodal Analysis using the [[PQplot]] by setting the flowing wellhead pressure (FWHP) equal to the current flowing line pressure (FLP) at the well head. <BR>Use | + | <td> Calculated with Nodal Analysis using the [[PQplot]] by setting the flowing wellhead pressure (FWHP) equal to the current flowing line pressure (FLP) at the well head. <BR>Use the current value of [[JD]].</td> |

| − | <td> Calculated with Nodal Analysis using the [[PQplot]] by using the largest tubing practical that will fit in the current well bore with a FWHP equal to the current FLP. The largest tubing size is approximately the casing drift diameter minus the tubing coupling diameter > 0.5 inches for clearance (see [[Pipe Catalog]]).<BR>Use | + | <td> Calculated with Nodal Analysis using the [[PQplot]] by using the largest tubing practical that will fit in the current well bore with a FWHP equal to the current FLP. The largest tubing size is approximately the casing drift diameter minus the tubing coupling diameter > 0.5 inches for clearance (see [[Pipe Catalog]]).<BR>Use [[JD]]=0.13.</td> |

</tr> | </tr> | ||

| Line 39: | Line 61: | ||

<td>Oil</td> | <td>Oil</td> | ||

<td>Flowing</td> | <td>Flowing</td> | ||

| − | <td>Calculated same as for the'''Gas Flowing''' case</td> | + | <td>Calculated the same way as for the '''Gas Flowing''' case</td> |

| + | <td>Calculated as absolute open flow (AOF).<BR>Use [[JD]]=1.27.</td> | ||

</tr> | </tr> | ||

| Line 45: | Line 68: | ||

<td>Oil</td> | <td>Oil</td> | ||

<td>Artificial Lift (ESP, Rod Pump, PCP)</td> | <td>Artificial Lift (ESP, Rod Pump, PCP)</td> | ||

| − | <td> | + | <td>Calculated by setting the flowing bottomhole pressure (Pwf) equal to the fluid level at the pump depth.<BR>Use the current value of [[JD]].</td> |

| + | <td>Calculated as absolute open flow (AOF).<BR>Use [[JD]]=1.27. <BR>Note: If WOP > all lift capacities thats good, must engineer a higher performance system.</td> | ||

</tr> | </tr> | ||

</table> | </table> | ||

| + | ===3. Enhancement Opportunities and Execution=== | ||

| + | [[Enhancement| Enhancement opportunities]] are identified by calculating the performance gap deriving from the difference between the [[Production Potential]] and actual well rates. | ||

| − | + | Then list of opportunities is ranked by production increments. | |

| − | + | As a result, the [[:category:Enhancement List | Well Enhancement List]] is generated with the best candidate on the top. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | The performance gaps are closed by executing the [[Enhancement| Enhancements]]. | |

| − | |||

| − | |||

| − | + | The success is tracked by [[Enhancement Tracking]] workflow. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | ==Discussion== | |

| − | + | [[:Category:Enhancement List | Enhancement List]] compiles the proven to work technologies into a practical management tool. It's implemented as a programing code of algorithms of the [[:Category:E&P Portal | E&P Portal]]. The code can be set up in the company database or in the cloud so that [[:Category:Enhancement List | Enhancement List]] will be automatically calculated on a daily basis. Such implementation allows management and engineers know and manage the [[Production Potential]] in real time. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | ==See also== | |

| − | + | [[Maximizing Petroleum Reservoir Production Using Gap Analysis]] | |

| − | + | [[Category:E&P Portal]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | {{#seo: | |

| − | + | |title=Oil and Gas Production Enhancement List | |

| − | + | |titlemode= replace | |

| − | + | |keywords=Production Enhancement, Oil and Gas | |

| − | + | |description=Enhancement List is raking of oil and gas well enhancements with the best on the top. | |

| − | + | }} | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Latest revision as of 08:22, 5 September 2019

Contents

Brief

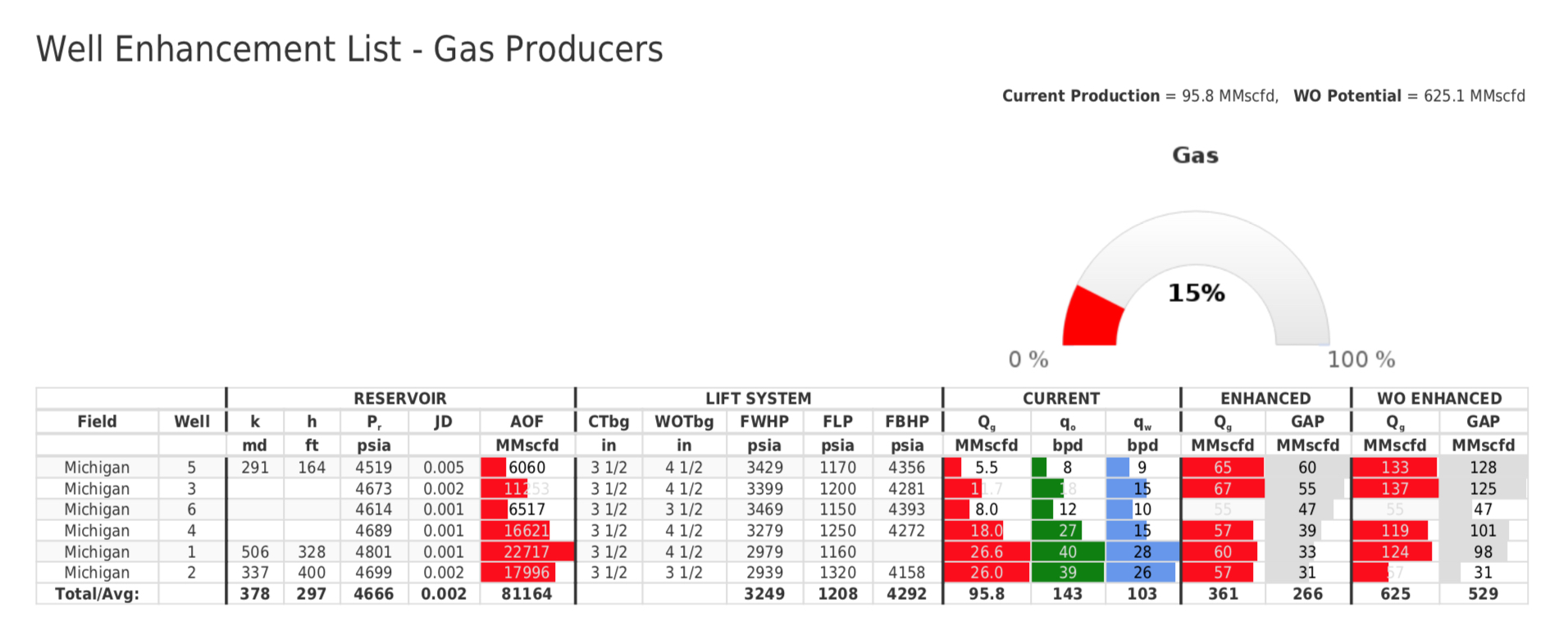

Enhancement List is a workflow for identifying the performance gaps based on the Gap Analysis.

The workflow produces the Enhancement List which is a ranking of the Enhancements with the best on the top.

Routine execution of the identified Enhancements unlocks the pathway to Production Potential and results in more production, improved recovery and increased earnings.

Workflow

1. Current Performance

Enhancement List requires a lot of data been measured and processed and without an automated system a lot of manual work.

The minimum required data set is:

- Field

- Reservoirs and PVT

- Well

- Well Type (producer, injector, history of change)

- Well Operation Type (flowing, artificial list, history of change)

- Well Daily Measures (specifically flowing rates, fluid levels, pressures)

- Deviation Survey

- Perforations

- kh & JD

- Well Downhole Equipment

- Well Design

2. Production Potential

Production Potential is calculated:

WHP and WOP

- Wellhead Potential (WHP) - is the maximum rate that can be achieved with existing well equipment with no workover (Choke open, Speedup the ESP, etc).

- Workover Potential (WOP) - is the maximum rate that can be achieved with workover. The assumption is that the current skin will be mitigated with better completion during the workover. And the largest tubing practical that will fit in the current well bore will be used.

Below is the Production Potential calculation logic of the E&P Portal:

| Well Primary Fluid | Well Operating Type | Wellhead Potential (WHP) | Workover Potential (WOP) |

|---|---|---|---|

| Gas | Flowing | Calculated with Nodal Analysis using the PQplot by setting the flowing wellhead pressure (FWHP) equal to the current flowing line pressure (FLP) at the well head. Use the current value of JD. |

Calculated with Nodal Analysis using the PQplot by using the largest tubing practical that will fit in the current well bore with a FWHP equal to the current FLP. The largest tubing size is approximately the casing drift diameter minus the tubing coupling diameter > 0.5 inches for clearance (see Pipe Catalog). Use JD=0.13. |

| Oil | Flowing | Calculated the same way as for the Gas Flowing case | Calculated as absolute open flow (AOF). Use JD=1.27. |

| Oil | Artificial Lift (ESP, Rod Pump, PCP) | Calculated by setting the flowing bottomhole pressure (Pwf) equal to the fluid level at the pump depth. Use the current value of JD. |

Calculated as absolute open flow (AOF). Use JD=1.27. Note: If WOP > all lift capacities thats good, must engineer a higher performance system. |

3. Enhancement Opportunities and Execution

Enhancement opportunities are identified by calculating the performance gap deriving from the difference between the Production Potential and actual well rates.

Then list of opportunities is ranked by production increments.

As a result, the Well Enhancement List is generated with the best candidate on the top.

The performance gaps are closed by executing the Enhancements.

The success is tracked by Enhancement Tracking workflow.

Discussion

Enhancement List compiles the proven to work technologies into a practical management tool. It's implemented as a programing code of algorithms of the E&P Portal. The code can be set up in the company database or in the cloud so that Enhancement List will be automatically calculated on a daily basis. Such implementation allows management and engineers know and manage the Production Potential in real time.

See also

Maximizing Petroleum Reservoir Production Using Gap Analysis

Pages in category "Enhancement List"

The following 5 pages are in this category, out of 5 total.