Gray correlation

Contents

Brief

Gray is an empirical two-phase flow correlation published in 1974 [1].

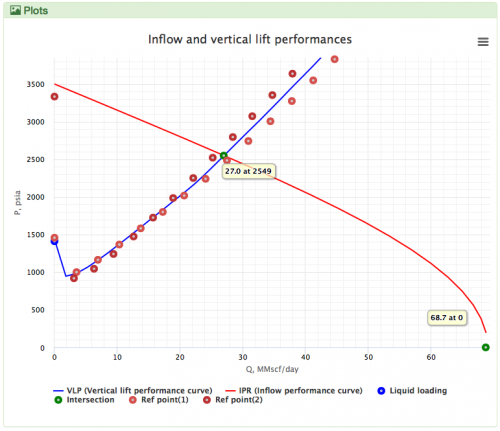

Gray is the default VLP correlation for the gas wells in the PQplot.

Math & Physics

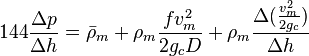

Following the law of conservation of energy the basic steady state flow equation is:

where

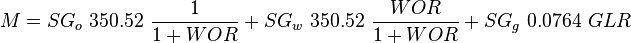

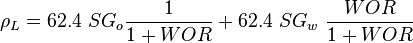

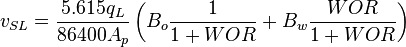

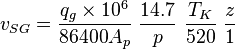

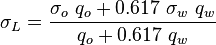

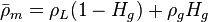

, slip mixture density [1].

, slip mixture density [1].

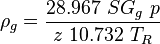

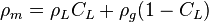

, no-slip mixture density [1].

, no-slip mixture density [1].

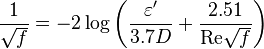

Colebrook–White [2] equation for the Darcy's friction factor:

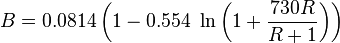

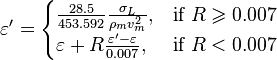

The pseudo wall roughness:

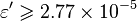

, with the limit

, with the limit  [1]

[1]

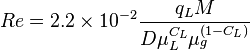

Reynolds two phase number:

Discussion

Why Gray correlation?

The Gray correlation was found to be the best of several initially tested ...— Nitesh Kumar l[5]

Workflow Hg & CL

Modifications

1. Use Fanning correlation for the dry gas (WGR=0 and OGR=0 case).

2. Use watercut instead of WOR to account for the OGR=0 case.

3. If the relative roughness:  use 0.05 in the Moody Diagram [3].

use 0.05 in the Moody Diagram [3].

4. If HL can't be calculated then HL = CL.

Nomenclature

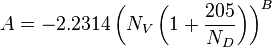

= correlation group, dimensionless

= correlation group, dimensionless = flow area, ft2

= flow area, ft2 = correlation group, dimensionless

= correlation group, dimensionless = formation factor, bbl/stb

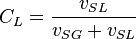

= formation factor, bbl/stb = no-slip holdup factor, dimensionless

= no-slip holdup factor, dimensionless = pipe diameter, ft

= pipe diameter, ft = depth, ft

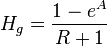

= depth, ft = holdup factor, dimensionless

= holdup factor, dimensionless = friction factor, dimensionless

= friction factor, dimensionless = gas-liquid ratio, scf/bbl

= gas-liquid ratio, scf/bbl = total mass of oil, water and gas associated with 1 bbl of liquid flowing into and out of the flow string, lbm/bbl

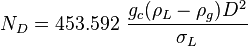

= total mass of oil, water and gas associated with 1 bbl of liquid flowing into and out of the flow string, lbm/bbl = pipe diameter number, dimensionless

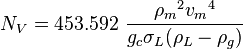

= pipe diameter number, dimensionless = velocity number, dimensionless

= velocity number, dimensionless = pressure, psia

= pressure, psia = conversion constant equal to 32.174049, lbmft / lbfsec2

= conversion constant equal to 32.174049, lbmft / lbfsec2 = production rate, bbl/d

= production rate, bbl/d = superficial liquid to gas ratio, dimensionless

= superficial liquid to gas ratio, dimensionless = Reynolds number, dimensionless

= Reynolds number, dimensionless = specific gravity, dimensionless

= specific gravity, dimensionless = temperature, °R or °K, follow the subscript

= temperature, °R or °K, follow the subscript = velocity, ft/sec

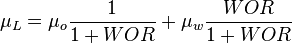

= velocity, ft/sec = water-oil ratio, bbl/bbl

= water-oil ratio, bbl/bbl = gas compressibility factor, dimensionless

= gas compressibility factor, dimensionless

Greek symbols

= absolute roughness, ft

= absolute roughness, ft = pseudo wall roughness, ft

= pseudo wall roughness, ft = viscosity, cp

= viscosity, cp = density, lbm/ft3

= density, lbm/ft3 = slip density, lbm/ft2

= slip density, lbm/ft2 = surface tension of liquid-air interface, dynes/cm

= surface tension of liquid-air interface, dynes/cm

Subscripts

g = gas

K = °K

L = liquid

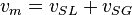

m = gas/liquid mixture

o = oil

R = °R

SL = superficial liquid

SG = superficial gas

w = water

References

- ↑ 1.00 1.01 1.02 1.03 1.04 1.05 1.06 1.07 1.08 1.09 1.10 Gray, H. E. (1974). "Vertical Flow Correlation in Gas Wells". User manual for API 14B, Subsurface controlled safety valve sizing computer program. API.

- ↑ Colebrook, C. F. (1938–1939). "Turbulent Flow in Pipes, With Particular Reference to the Transition Region Between the Smooth and Rough Pipe Laws"

. Journal of the Institution of Civil Engineers. London, England. 11: 133–156.

. Journal of the Institution of Civil Engineers. London, England. 11: 133–156.

- ↑ 3.0 3.1 Moody, L. F. (1944). "Friction factors for pipe flow"

. Transactions of the ASME. 66 (8): 671–684.

. Transactions of the ASME. 66 (8): 671–684.

- ↑ 4.0 4.1 Hagedorn, A. R.; Brown, K. E. (1965). "Experimental study of pressure gradients occurring during continuous two-phase flow in small-diameter vertical conduits". Journal of Petroleum Technology. 17(04): 475–484.

- ↑ Kumar, N.; Lea, J. F. (January 1, 2005). "Improvements for Flow Correlations for Gas Wells Experiencing Liquid Loading"

(SPE-92049-MS).

(SPE-92049-MS).

- ↑ 6.0 6.1 6.2 Lyons, W.C. (1996). Standard handbook of petroleum and natural gas engineering. 2. Houston, TX: Gulf Professional Publishing. ISBN 0-88415-643-5.