Difference between revisions of "Category: FracDesign"

(→Comparison study) |

(→Typical applications) |

||

| Line 14: | Line 14: | ||

== Typical applications == | == Typical applications == | ||

| − | * Calculating the pumping schedule required to | + | * Calculating the pumping schedule required to achieve optimal fracture geometry in design mode |

* Providing the input pumping schedule for more complex fracture simulators to use as a fracture design starting point (initial guess) | * Providing the input pumping schedule for more complex fracture simulators to use as a fracture design starting point (initial guess) | ||

* Optimization of hydraulic fracture design with '''Unified Fracture Design'''<ref name=UFD2002/> | * Optimization of hydraulic fracture design with '''Unified Fracture Design'''<ref name=UFD2002/> | ||

Revision as of 07:45, 29 October 2018

Contents

Brief

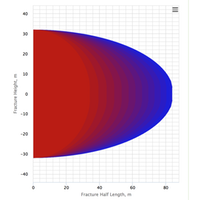

fracDesign is a tool for designing a hydraulic fracture treatment in pengtools.

For the given set of reservoir, fluid and proppant properties fracDesign calculates the pumping schedule which will create the optimal fracture geometry to achieve maximum well’s productivity.

fracDesign algorithm is based on widely used fracture PKN and KGD models (see [1]). Pumping schedule realizes the optimal fracture geometry and assures uniform placement of the proppant (see [2]). If the optimum placement cannot be realized by traditional means, a TSO design option is available. Like any other model fracDesign inevitably uses a number of mathematical idealizations.

fracDesignis available online at www.pengtools.com.

Typical applications

- Calculating the pumping schedule required to achieve optimal fracture geometry in design mode

- Providing the input pumping schedule for more complex fracture simulators to use as a fracture design starting point (initial guess)

- Optimization of hydraulic fracture design with Unified Fracture Design[2]

- TSO design for high permeable and soft formations where high fracture flow conductivity (width) is needed

- Simulation of the fracture geometry based on the given pumping schedule with PKN and KGD models in simulation mode

- Sensitivity studies: By modifying various input parameters, an intuitive feel for their relative importance in treatment design and final fractured well performance can be rapidly acquired

Math & Physics

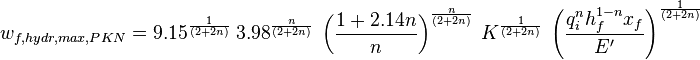

- hydraulic maximum fracture width PKN (ref[1] eq 9.53)

- hydraulic maximum fracture width PKN (ref[1] eq 9.53)

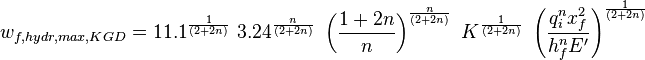

- hydraulic maximum fracture width KGD (ref[1] eq 9.55)

- hydraulic maximum fracture width KGD (ref[1] eq 9.55)

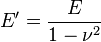

- plain strain modulus

- plain strain modulus

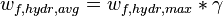

- hydraulic average fracture width

- hydraulic average fracture width

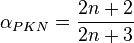

- shape factor PKN (ref[1] eq 9.10)

- shape factor PKN (ref[1] eq 9.10)

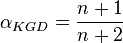

- shape factor KGD (ref[1] eq 9.24)

- shape factor KGD (ref[1] eq 9.24)

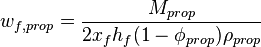

- propped fracture width

- propped fracture width

- mass balance equation (ref[1] eq 8.1)

- mass balance equation (ref[1] eq 8.1)

- injected volume into one fracture wing

- injected volume into one fracture wing

- the area of one face of one wing for rectangular fracture shape

- the area of one face of one wing for rectangular fracture shape

- the area of one face of one wing for elliptic fracture shape

- the area of one face of one wing for elliptic fracture shape

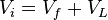

- volume of fluid contained in one fracture wing

- volume of fluid contained in one fracture wing

- volume of fluid leak-off to formation through the two created fracture surfaces of one wing

- volume of fluid leak-off to formation through the two created fracture surfaces of one wing

- mass balance equation (ref[2] eq 4.6)

- mass balance equation (ref[2] eq 4.6)

- fluid efficiency

- fluid efficiency

Opening time distribution factor KL

Nolte opening time distribution factor KL

- (ref[1] eq 8.36)

- (ref[1] eq 8.36)

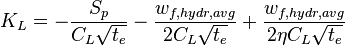

Carter opening time distribution factor KL

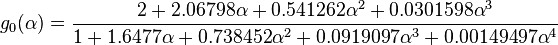

(ref [2] eq 4.8)

(ref [2] eq 4.8)

where:

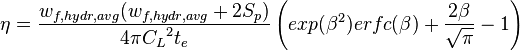

(ref [2] eq 4.9)

(ref [2] eq 4.9)

and:

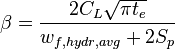

(ref [2] eq 4.9)

(ref [2] eq 4.9)

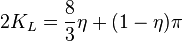

Nolte G-function for opening time distribution factor KL

(ref [2] eq 4.12)

(ref [2] eq 4.12)

where:

Pumping schedule

According to Nolte[3] the schedule is derived from the following assumptions:

- the whole length created should be propped

- at the end of pumping, the proppant distribution in the fracture should be uniform

- the proppant schedule should be of the form of a delayed power law with the Nolte's exponent and the fraction of pad being equal

- Nolte exponent

- Nolte exponent

- pad pumping time

- pad pumping time

- proppant concentration at the end of pumping

- proppant concentration at the end of pumping

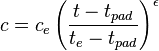

- slurry concentration vs time

- slurry concentration vs time

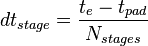

- ramping stage duration

- ramping stage duration

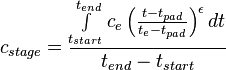

- ramping stage slurry concentration

- ramping stage slurry concentration

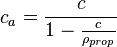

- conversion form slurry concentration (proppant mass per unit of injected slurry) to clean concentration (proppant mass per unit of injected clean/base/"neat" fluid)

- conversion form slurry concentration (proppant mass per unit of injected slurry) to clean concentration (proppant mass per unit of injected clean/base/"neat" fluid)

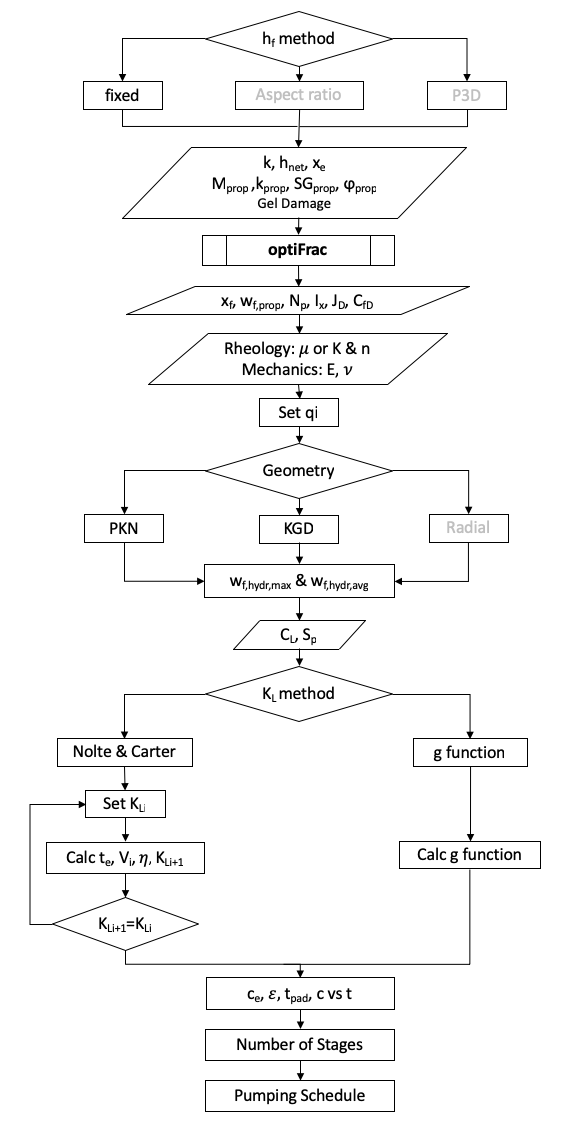

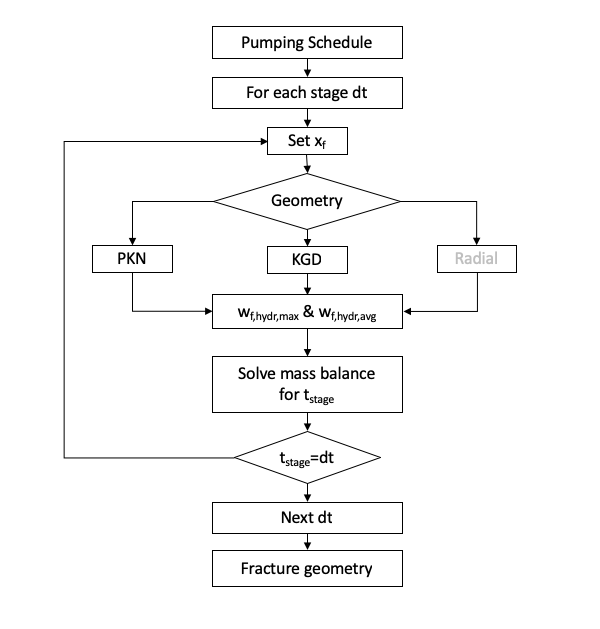

Flow Diagram

Design mode

Simulation mode

Workflow

Design mode

- Input the fracture height, hf

- Run optiFrac to get optimum xf and wf, prop

- Calculate maximum and average hydraulic fracture widths : wf,hydr,max and wf,hydr,avg

- Calculate opening time distribution factor, KL

- Solve mass balance equation for total pumping time, te

- Calculate fluid efficiency, η

- Calculate Nolte's exponent, ε

- Calculate pad time, tpad

- Calculate proppant concentration at the end of pumping, ce

- Calculate slurry concentration vs time curve, c vs t

- Set the number of stages, Nstage

- Calculate slurry concentration at each stage, cstage

Simulation mode

- Input the fracture height, hf

- Input the pumping schedule, dt, cstage for each Nstage

- For each stage duration, dt

- Set the xf

- Calculate maximum and average hydraulic fracture widths : wf,hydr,max and wf,hydr,avg

- Calculate opening time distribution factor, KL

- Solve mass balance equation for total pumping time, tstage

- Iterate until tstage=dt

- Move to the next stage

Note that: Distribution of the proppant in the fracture is not modelled in the simulation mode. Only geometry evolution and byproducts are simulated under assumption that proppant is uniformly distributed in fracture.

TSO Design

TSO effect is supported by the fracDesign using the TSO Design option.

TSO occurs when dry-to-wet fracture width ratio, δ, is becoming larger than some critical value set by the user.

Dry-to-wet fracture width ratio, δ, is specified by user in the Fracture tuning input section. The value near 0.7 is recommended in Economides, Oligney, Valko (2002).

If TSO Design option is ON and during conventional design critical dry-to-wet width ratio, δ, was reached fracture length stop to grow and width became a function of injected proppant. Then we add additional step with injected concentration equivalent to critical dry-to-wet width ratio. Duration of this step is calculated in order to place all the proppant.

If TSO Design option is OFF and during conventional design critical dry-to-wet width ratio, δ, was reached we stop addition of proppant at this place and show the warning message:

”Tip screen-out occurs. Not all the proppant is placed. Try TSO design.”

Also if concentration of injected slurry became larger then defined by user maximum concentration we stop addition of proppant and show the warning message:

”Maximum concentration reached. Not all the proppant is placed. Try TSO design”

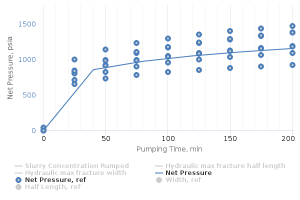

Comparison study

1. fracDesign Comparison Study 1 Warpinski. The fracDesign calculates 4 cases described in the paper and shows good agreement in results.

Main features

- PKN and KGD fracture geometry models

- optiFrac workflow on fracture geometry optimization

- Slurry concentration versus time pumping schedule as plot and table

- Fracture length and width profiles vs time plots

- Net pressure profiles vs time as plot and table

- Practical pumping constrains and Fracture tuning options

- Detailed output table with calculated fracture design parameters

- Sensitivity option with benchmark to potential

- Simulation mode: calculating the fracture geometry from the given pumping schedule

- "New model" button resets input values to the default values.

- Switch between Metric and Field units.

- Save/load models to the files and to the user’s cloud.

- Export pdf report containing input parameters, calculated values and the chart.

- Share models to the public cloud or by using model’s link.

- Continue your work from where you stopped: last saved model will be automatically opened.

- Download the chart as an image or data and print (upper-right corner chart’s button).

Nomenclature

= surface area, m2

= surface area, m2 = clean concentration (proppant mass per unit of injected clean/base/"neat" fluid), kg/m3

= clean concentration (proppant mass per unit of injected clean/base/"neat" fluid), kg/m3 = leak-off coefficient, m/s0.5

= leak-off coefficient, m/s0.5 = slurry concentration (proppant mass per unit of injected slurry), kg/m3

= slurry concentration (proppant mass per unit of injected slurry), kg/m3 = time step, sec

= time step, sec = plain strain modulus, Pa

= plain strain modulus, Pa = Young's Modulus, Pa

= Young's Modulus, Pa = height, m

= height, m = opening time distribution factor, dimensionless

= opening time distribution factor, dimensionless = rheology consistency index, Pa*sn

= rheology consistency index, Pa*sn = mass, kg

= mass, kg = rheology flow behavior index, dimensionless

= rheology flow behavior index, dimensionless = slurry injection rate for one wing, m3/sec

= slurry injection rate for one wing, m3/sec = spurt loss coefficient, m

= spurt loss coefficient, m = pumping time, sec

= pumping time, sec = volume, m3

= volume, m3 = width, m

= width, m = fracture half-length, m

= fracture half-length, m

Greek symbols

= dry to wet width ratio at the end of pumping, usually 0.5-0.7

= dry to wet width ratio at the end of pumping, usually 0.5-0.7 = Nolte exponent, dimensionless

= Nolte exponent, dimensionless = fluid efficiency, fraction

= fluid efficiency, fraction = geometric factor in vertical direction, dimensionless

= geometric factor in vertical direction, dimensionless = Poisson's ratio, dimensionless

= Poisson's ratio, dimensionless  = porosity, fraction

= porosity, fraction = 3.1415

= 3.1415 = density, kg/m3

= density, kg/m3

Subscripts

- avg = average

- e = end of pumping

- f = fracture

- gross = gross

- hydr = hydraulic

- i = injected

- KGD = Khristianovic-Geertsma-de Klerk geometry

- L = leak-off

- max = maximum

- net = net

- pad = pad

- PKN = Perkins-Kern-Nordgren geometry

- prop = propped or proppant

- r = reservoir

References

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 1.6 Valko, Peter; Economides, Michael J. (1995). Hydraulic fracture mechanics. Texas A & M University: John Wiley and Sons.

- ↑ 2.0 2.1 2.2 2.3 2.4 2.5 2.6 Economides, Michael J.; Oligney, Ronald; Valko, Peter (2002). Unified Fracture Design: Bridging the Gap Between Theory and Practice. Alvin, Texas: Orsa Press.

- ↑ Nolte, K.G. (1986). "Determination of Proppant and Fluid Schedules From Fracturing-Pressure Decline"

(SPE-13278-PA). Society of Petroleum Engineers.

(SPE-13278-PA). Society of Petroleum Engineers.

Pages in category "FracDesign"

The following 8 pages are in this category, out of 8 total.