Beggs and Brill correlation

Contents

Brief

Beggs and Brill is an empirical two-phase flow correlation published in 1972 [1].

It distinguish between 4 flow regimes.

Beggs and Brill is the default VLP correlation in sPipe.

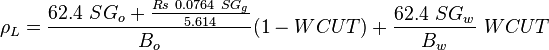

Math & Physics

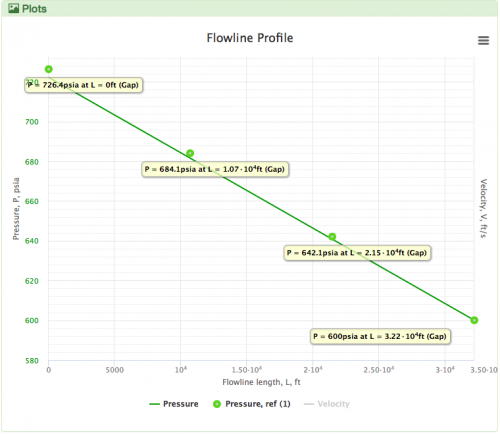

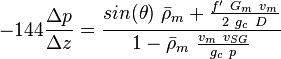

Fluid flow energy balance

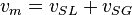

where

Flow patterns

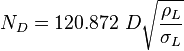

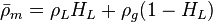

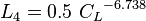

Froude number:

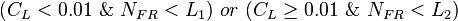

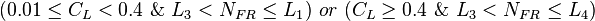

SEGREGATED:  [2]

[2]

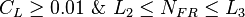

TRANSITION:  [2]

[2]

INTERMITTENT:  [2]

[2]

DISTRIBUTED:  [2]

[2]

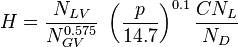

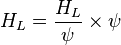

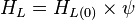

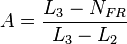

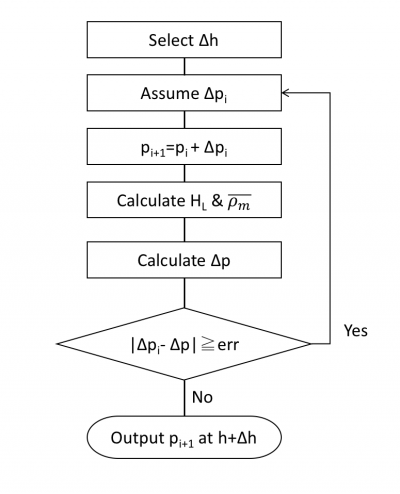

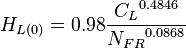

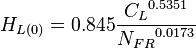

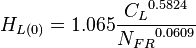

Liquid Holdup HL

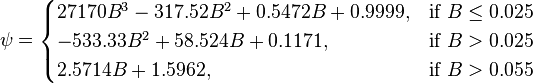

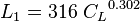

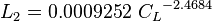

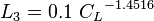

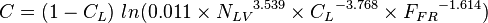

SEGREGATED, INTERMITTENT, DISTRIBUTED:  [2]

[2]

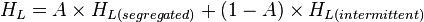

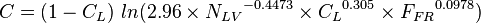

TRANSITION:  [2]

[2]

where:

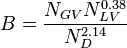

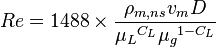

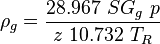

Friction factor

No slip Reynolds two phase number:

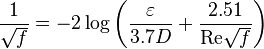

Colebrook–White [3] equation for the Darcy's friction factor:

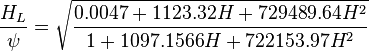

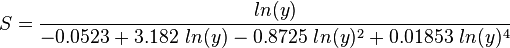

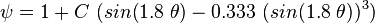

Corrected two phase friction factor:

where

and

with constraint:

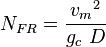

Discussion

Why Hagedorn and Brown?

One of the consistently best correlations ...— Michael Economides et al[5]

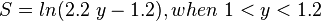

Flow Diagram

Workflow

Determine the flow pattern: SEGREGATED, INTERMITTENT, DISTRIBUTED, TRANSITION.

with the constraint  [2]

[2]

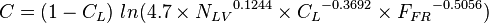

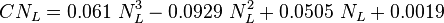

C Uphill:

C Downhill:

- ALL:

[2]

[2]

Modifications

1. Use the no-slip holdup when the original empirical correlation predicts a liquid holdup HL less than the no-slip holdup [5].

2. Use the Griffith correlation to define the bubble flow regime[5] and calculate HL.

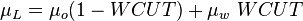

3. Use watercut instead of WOR to account for the watercut = 100%.

Nomenclature

= flow area, ft2

= flow area, ft2 = correlation group, dimensionless

= correlation group, dimensionless = formation factor, bbl/stb

= formation factor, bbl/stb = coefficient for liquid viscosity number, dimensionless

= coefficient for liquid viscosity number, dimensionless = pipe diameter, ft

= pipe diameter, ft = depth, ft

= depth, ft = correlation group, dimensionless

= correlation group, dimensionless = liquid holdup factor, dimensionless

= liquid holdup factor, dimensionless = friction factor, dimensionless

= friction factor, dimensionless = gas-liquid ratio, scf/bbl

= gas-liquid ratio, scf/bbl = total mass of oil, water and gas associated with 1 bbl of liquid flowing into and out of the flow string, lbm/bbl

= total mass of oil, water and gas associated with 1 bbl of liquid flowing into and out of the flow string, lbm/bbl = pipe diameter number, dimensionless

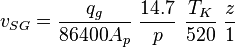

= pipe diameter number, dimensionless = gas velocity number, dimensionless

= gas velocity number, dimensionless = liquid viscosity number, dimensionless

= liquid viscosity number, dimensionless = liquid velocity number, dimensionless

= liquid velocity number, dimensionless = pressure, psia

= pressure, psia = conversion constant equal to 32.174049, lbmft / lbfsec2

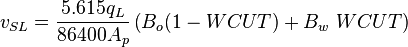

= conversion constant equal to 32.174049, lbmft / lbfsec2 = total liquid production rate, bbl/d

= total liquid production rate, bbl/d = Reynolds number, dimensionless

= Reynolds number, dimensionless = solution gas-oil ratio, scf/stb

= solution gas-oil ratio, scf/stb = specific gravity, dimensionless

= specific gravity, dimensionless = temperature, °R or °K, follow the subscript

= temperature, °R or °K, follow the subscript = velocity, ft/sec

= velocity, ft/sec = water-oil ratio, bbl/bbl

= water-oil ratio, bbl/bbl = gas compressibility factor, dimensionless

= gas compressibility factor, dimensionless

Greek symbols

= absolute roughness, ft

= absolute roughness, ft = viscosity, cp

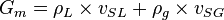

= viscosity, cp = density, lbm/ft3

= density, lbm/ft3 = integrated average density at flowing conditions, lbm/ft2

= integrated average density at flowing conditions, lbm/ft2 = surface tension of liquid-air interface, dynes/cm (ref. values: 72 - water, 35 - oil)

= surface tension of liquid-air interface, dynes/cm (ref. values: 72 - water, 35 - oil) = secondary correlation factor, dimensionless

= secondary correlation factor, dimensionless

Subscripts

g = gas

K = °K

L = liquid

m = gas/liquid mixture

o = oil

R = °R

SL = superficial liquid

SG = superficial gas

w = water

References

- ↑ 1.0 1.1 1.2 1.3 Beggs, H. D.; Brill, J. P. (May 1973). "A Study of Two-Phase Flow in Inclined Pipes"

. Journal of Petroleum Technology. AIME. 255 (SPE-4007-PA).

. Journal of Petroleum Technology. AIME. 255 (SPE-4007-PA).

- ↑ 2.00 2.01 2.02 2.03 2.04 2.05 2.06 2.07 2.08 2.09 2.10 2.11 2.12 2.13 2.14 2.15 2.16 2.17 2.18 2.19 2.20 2.21 2.22 2.23 2.24 Cite error: Invalid

<ref>tag; no text was provided for refs namedBB1991 - ↑ Colebrook, C. F. (1938–1939). "Turbulent Flow in Pipes, With Particular Reference to the Transition Region Between the Smooth and Rough Pipe Laws"

. Journal of the Institution of Civil Engineers. London, England. 11: 133–156.

. Journal of the Institution of Civil Engineers. London, England. 11: 133–156.

- ↑ Moody, L. F. (1944). "Friction factors for pipe flow"

. Transactions of the ASME. 66 (8): 671–684.

. Transactions of the ASME. 66 (8): 671–684.

- ↑ 5.0 5.1 5.2 5.3 5.4 5.5 Economides, M.J.; Hill, A.D.; Economides, C.E.; Zhu, D. (2013). Petroleum Production Systems (2 ed.). Westford, Massachusetts: Prentice Hall. ISBN 978-0-13-703158-0.

- ↑ 6.0 6.1 6.2 6.3 6.4 6.5 6.6 Lyons, W.C. (1996). Standard handbook of petroleum and natural gas engineering. 2. Houston, TX: Gulf Professional Publishing. ISBN 0-88415-643-5.

- ↑ 7.0 7.1 7.2 7.3 7.4 Cite error: Invalid

<ref>tag; no text was provided for refs namedHB - ↑ 8.0 8.1 Trina, S. (2010). An integrated horizontal and vertical flow simulation with application to wax precipitation (Master of Engineering Thesis). Canada: Memorial University of Newfoundland.

![N_L = 0.15726\ \mu_L \sqrt[4]{\frac{1}{\rho_L \sigma_L^3}}](/images/math/b/2/0/b207fe79b4a4ee53d466e182791ca737.png)

![N_{LV} = 1.938\ v_{SL}\ \sqrt[4]{\frac{\rho_L}{\sigma_L}}](/images/math/d/d/8/dd824df0b6ec22aa724161b929e993fe.png)

![N_{GV} = 1.938\ v_{SG}\ \sqrt[4]{\frac{\rho_L}{\sigma_L}}](/images/math/3/6/4/364153c39c1657b3b7bab8f7ed710e60.png)