Difference between revisions of "Gas Flowing Material Balance"

(→Workflow) |

(→Workflow) |

||

| Line 35: | Line 35: | ||

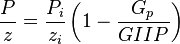

## Calculate the <math> \frac{\bar{P}}{z}</math> | ## Calculate the <math> \frac{\bar{P}}{z}</math> | ||

#Calculate the gray [[JD]] curve: | #Calculate the gray [[JD]] curve: | ||

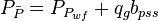

| − | ##Calculate the gas productivity index: <math>J=\frac{\bar{P}- | + | ##Calculate the gas productivity index: <math>J=\frac{\bar{P}-P_P_{wf}}{q_g}</math> |

## | ## | ||

Revision as of 08:19, 11 December 2017

Contents

Brief

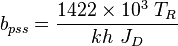

Gas Flowing Material Balance is the advanced engineering technique to determine the Reservoirs GIIP and recovery as well as Well's EUR and JD.

Gas Flowing Material Balance is applied on the Well level given readily available well flowing data: production rate and tubing head pressure.

The interpretation technique is fitting the data points with the straight line to estimate GIIP and JD.

Math & Physics

Combining the gas pseudo state flow equation and the Gas Material Balance equation to get Gas Flowing Material Balance equation:

where

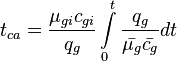

Material balance pseudo-time:

Discussion

Workflow

- Calculate the red

line:

line:

-

- Calculate the orange

curve:

curve:

- Given the flowing wellhead pressures, calculate the flowing bottomhole pressures,

- Convert the flowing pressures to pseudopressures,

- Calculate the

- Calculate the pseudopressure,

- Convert the pseudopressure to pressure,

- Calculate the

- Given the flowing wellhead pressures, calculate the flowing bottomhole pressures,

- Calculate the gray JD curve:

- Calculate the gas productivity index: Failed to parse (PNG conversion failed; check for correct installation of latex and dvipng (or dvips + gs + convert)): J=\frac{\bar{P}-P_P_{wf}}{q_g}

bsss

Calculate initial pseudopressure,  Calculate material balance pseudo-time,

Calculate material balance pseudo-time,  Plot

Plot  versus

versus  . The intercept gives

. The intercept gives  and

and  .

Calculate the average reservoir pseudopressure from Gas Flowing Material Balance equation,

.

Calculate the average reservoir pseudopressure from Gas Flowing Material Balance equation,

Data required

Nomenclature

= flow area, ft2

= flow area, ft2 = correlation group, dimensionless

= correlation group, dimensionless = formation factor, bbl/stb

= formation factor, bbl/stb = coefficient for liquid viscosity number, dimensionless

= coefficient for liquid viscosity number, dimensionless = pipe diameter, ft

= pipe diameter, ft = depth, ft

= depth, ft = correlation group, dimensionless

= correlation group, dimensionless = liquid holdup factor, dimensionless

= liquid holdup factor, dimensionless = friction factor, dimensionless

= friction factor, dimensionless = gas-liquid ratio, scf/bbl

= gas-liquid ratio, scf/bbl = total mass of oil, water and gas associated with 1 bbl of liquid flowing into and out of the flow string, lbm/bbl

= total mass of oil, water and gas associated with 1 bbl of liquid flowing into and out of the flow string, lbm/bbl = pipe diameter number, dimensionless

= pipe diameter number, dimensionless = gas velocity number, dimensionless

= gas velocity number, dimensionless = liquid viscosity number, dimensionless

= liquid viscosity number, dimensionless = liquid velocity number, dimensionless

= liquid velocity number, dimensionless = pressure, psia

= pressure, psia = conversion constant equal to 32.174049, lbmft / lbfsec2

= conversion constant equal to 32.174049, lbmft / lbfsec2 = total liquid production rate, bbl/d

= total liquid production rate, bbl/d = Reynolds number, dimensionless

= Reynolds number, dimensionless = solution gas-oil ratio, scf/stb

= solution gas-oil ratio, scf/stb = specific gravity, dimensionless

= specific gravity, dimensionless = temperature, °R or °K, follow the subscript

= temperature, °R or °K, follow the subscript = velocity, ft/sec

= velocity, ft/sec = water-oil ratio, bbl/bbl

= water-oil ratio, bbl/bbl = gas compressibility factor, dimensionless

= gas compressibility factor, dimensionless

Greek symbols

= absolute roughness, ft

= absolute roughness, ft = viscosity, cp

= viscosity, cp = density, lbm/ft3

= density, lbm/ft3 = integrated average density at flowing conditions, lbm/ft3

= integrated average density at flowing conditions, lbm/ft3 = surface tension of liquid-air interface, dynes/cm (ref. values: 72 - water, 35 - oil)

= surface tension of liquid-air interface, dynes/cm (ref. values: 72 - water, 35 - oil) = secondary correlation factor, dimensionless

= secondary correlation factor, dimensionless

Subscripts

- g = gas

- K = °K

- L = liquid

- m = gas/liquid mixture

- o = oil

- R = °R

- SL = superficial liquid

- SG = superficial gas

- w = water

References

- ↑ Mattar, L.; Anderson, D (2005). "Dynamic Material Balance (Oil or Gas-In-Place Without Shut-Ins)" (PDF). CIPC.