Difference between revisions of "OnPlan Comparison Study 2 Warpinski"

(→Comparison) |

|||

| (10 intermediate revisions by the same user not shown) | |||

| Line 10: | Line 10: | ||

{{Quote| text = This study is a comparison of hydraulic fracture models run using test data from the GRI Staged Field Experiment No. 3. Models compared include 2D, pseudo-3D, and 3D codes, run on up to eight different cases. Documented in this comparison are the differences in length, height, width, pressure, and efficiency. The purpose of this study is to provide the completions engineer with a practical comparison of the available models so that rational decisions can be made as to which model is optimal for a given application. | source = Warpinski et al <ref name= Warpinski />}} | {{Quote| text = This study is a comparison of hydraulic fracture models run using test data from the GRI Staged Field Experiment No. 3. Models compared include 2D, pseudo-3D, and 3D codes, run on up to eight different cases. Documented in this comparison are the differences in length, height, width, pressure, and efficiency. The purpose of this study is to provide the completions engineer with a practical comparison of the available models so that rational decisions can be made as to which model is optimal for a given application. | source = Warpinski et al <ref name= Warpinski />}} | ||

| − | ===Simulators=== | + | ===Hydraulic Fracturing Simulators=== |

Planar 3D models: | Planar 3D models: | ||

| Line 81: | Line 81: | ||

Single-Layer cases 1 and 2 show good agreement between [[:category:onPlan | onPlan]] and paper results. | Single-Layer cases 1 and 2 show good agreement between [[:category:onPlan | onPlan]] and paper results. | ||

| − | 3-Layer and 5-Layer cases 3 - 6 show that [[:category:onPlan | onPlan]] generally predicts less height thus more length and less width | + | 3-Layer and 5-Layer cases 3 - 6 show that [[:category:onPlan | onPlan]] generally predicts less height thus more length and less width. |

| + | {{Quote| text = These comparisons show that differences in calculated fracture lengths can be large, as much as a factor of three difference. Fracture heights, for the multi-layer cases, can differ by more than 50%. Net pressures also differ by a factor of two. | ||

| + | | source = Warpinski et al <ref name= Warpinski />}} | ||

<table> | <table> | ||

| Line 135: | Line 137: | ||

[[Category:onPlan]] | [[Category:onPlan]] | ||

| + | [[Category:pengtools]] | ||

{{#seo: | {{#seo: | ||

| − | |title=Hydraulic Fracturing Case Study | + | |title=Hydraulic Fracturing Case Study Warpinski vs onPlan |

|titlemode= replace | |titlemode= replace | ||

|keywords=hydraulic fracturing, hydraulic fracturing simulation software, petroleum engineering software, petroleum engineering, warpinski, case study | |keywords=hydraulic fracturing, hydraulic fracturing simulation software, petroleum engineering software, petroleum engineering, warpinski, case study | ||

| − | |description= | + | |description=Hydraulic fracturing simulator onPlan vs Warpinski SPE paper 25890: Comparison Study of Hydraulic Fracturing Models. |

}} | }} | ||

Latest revision as of 08:26, 15 November 2019

Contents

Brief

The case study is based on Warpinski [1] paper published in 1994.

The onPlan calculates 6 cases described in the paper and shows good agreement in results.

Inputs

Paper Summary

This study is a comparison of hydraulic fracture models run using test data from the GRI Staged Field Experiment No. 3. Models compared include 2D, pseudo-3D, and 3D codes, run on up to eight different cases. Documented in this comparison are the differences in length, height, width, pressure, and efficiency. The purpose of this study is to provide the completions engineer with a practical comparison of the available models so that rational decisions can be made as to which model is optimal for a given application.— Warpinski et al [1]

Hydraulic Fracturing Simulators

Planar 3D models:

- TerraFrac of TerraTek Inc.

- HYFRAC3D by S.H. Advani of Lehigh U. - Planar 3D model

- GOHFER by by Marathon Oil Co. - a unique finite-difference simulator

Planar pseudo-3D models:

- STIMPLAN of NSI Inc.

- ENERFRAC of Shell

- TRIFRAC of S.A. Holditch & Assocs. Inc.

- FRACPRO of Reservoir Engineering Systems (RES) Inc.

- MFRAC-II of Meyer& Assocs.

Classic Perkins-Kern-Nordgren (PKN) and Geertsma-deKlerk (GDK) model:

- PROP of Halliburton

- Chevron 2D model

- Conoco 2D model

- Shell 2D model

- pseudo-3D models run in constant-height mode

Cases

| CASE | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Formation Properties | ||||||

| Resesvoir and rock data | Single-Layer | Single-Layer | 3-Layer | 3-Layer | 5-Layer | 5-Layer |

| Fluid Properties | ||||||

| Viscosity, cP | 200 | 200 | 200 | |||

| K, (lbf-sec^n)/ft^2 | 0.06 | 0.06 | 0.06 | |||

| n | 0.5 | 0.5 | 0.5 | |||

| Leak-off, ft/min^0.5 | 0.00025 | 0.00025 | 0.00025 | 0.00025 | 0.00025 | 0.00025 |

| Spurt loss, gal/ft^2 | 0 | 0 | 0 | 0 | 0 | 0 |

| Other Data | ||||||

| Pumping rate, bbl/min | 50 | 50 | 50 | 50 | 50 | 50 |

| Pumping volume, bbl | 10000 | 10000 | 10000 | 10000 | 10000 | 10000 |

| Pupming time, min | 200 | 200 | 200 | 200 | 200 | 200 |

| Proppant | None | None | None | None | None | None |

Rock and reservoir data:

| Interval | Depth (ft) | Zone Thickness (ft) | In Situ Stress (psi) | Poisson's Ratio | Young's Modulus (10^6 psi) | Fracture Toughness (psi/in^0.5) |

|---|---|---|---|---|---|---|

| Single-Layer Case | ||||||

| 1 | 9170-9340 | 170 | 5700 | 0.21 | 8.5 | 2000 |

| 3-Layer Case | ||||||

| 1 | 8990-9170 | 180 | 7150 | 0.3 | 6.5 | 2000 |

| 2 | 9170-9340 | 170 | 5700 | 0.21 | 8.5 | 2000 |

| 3 | 9340-9650 | 310 | 7350 | 0.29 | 5.5 | 2000 |

| 5-Layer Case | ||||||

| 1 | 8990-9170 | 180 | 7150 | 0.3 | 6.5 | 2000 |

| 2 | 9170-9340 | 170 | 5700 | 0.21 | 8.5 | 2000 |

| 3 | 9340-9380 | 40 | 7350 | 0.26 | 5.4 | 2000 |

| 4 | 9380-9455 | 75 | 5800 | 0.2 | 7.9 | 2000 |

| 5 | 9455-9650 | 195 | 8200 | 0.3 | 4.0 | 2000 |

Perforations data:

The well was perforated between 9225 to 9250 ft and 9285 to 9330 ft.

Comparison

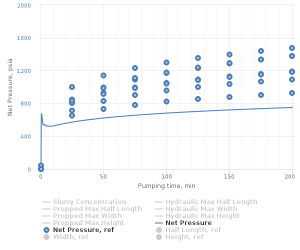

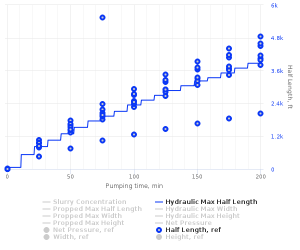

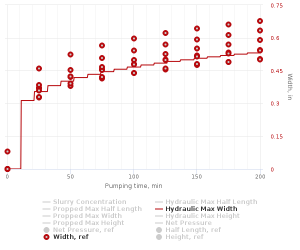

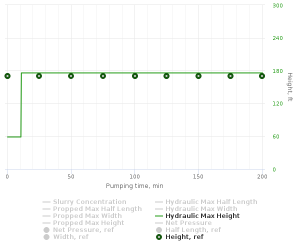

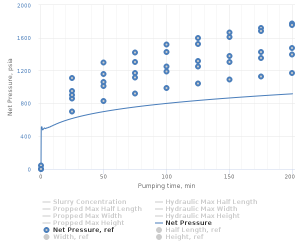

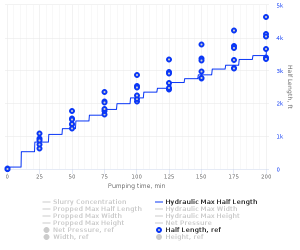

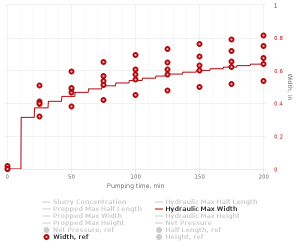

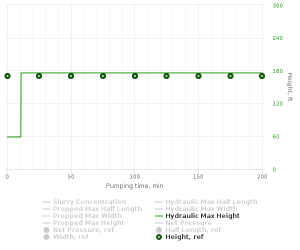

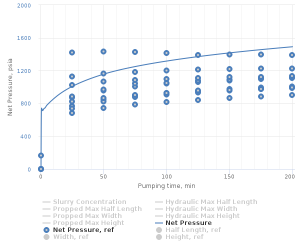

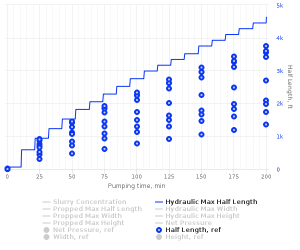

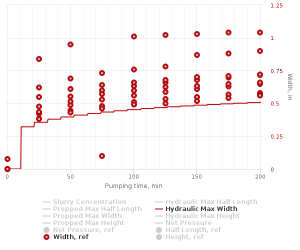

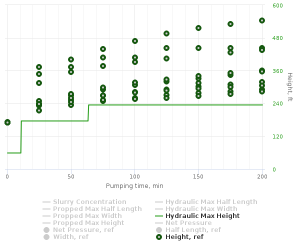

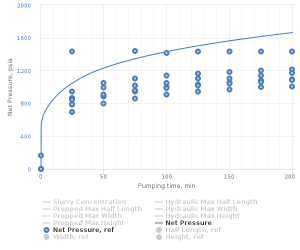

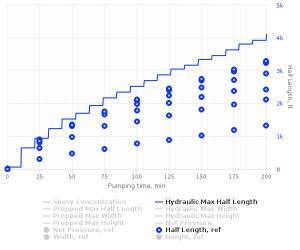

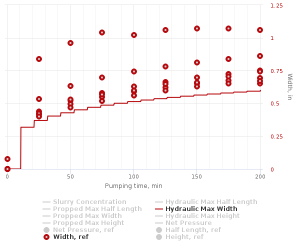

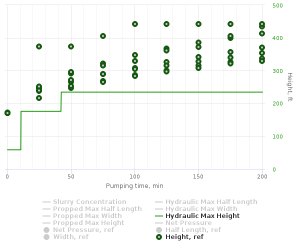

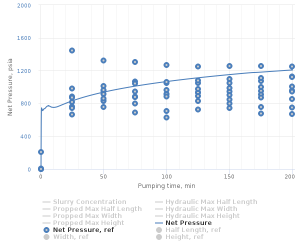

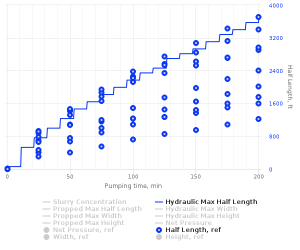

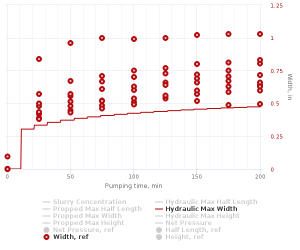

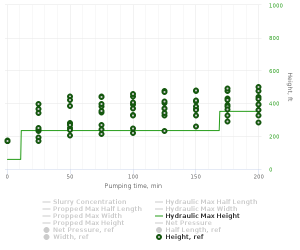

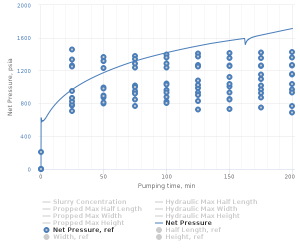

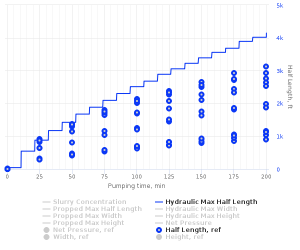

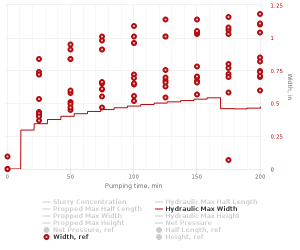

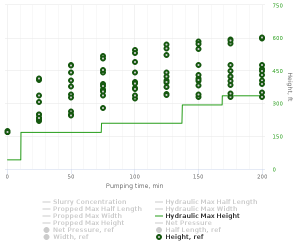

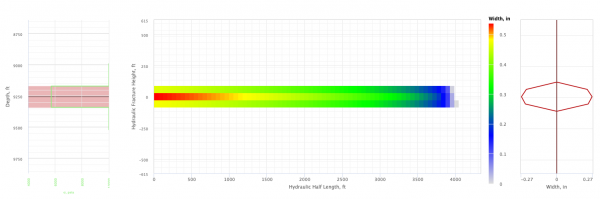

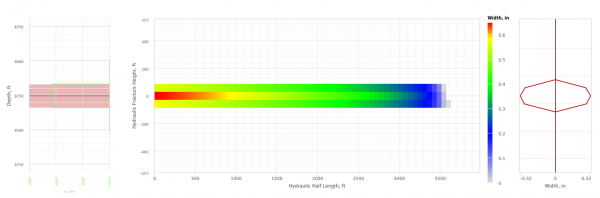

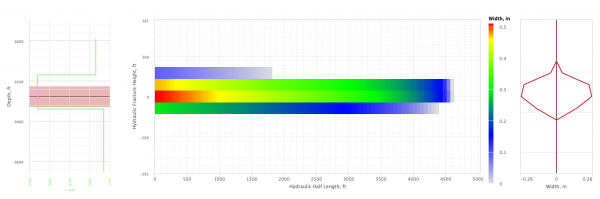

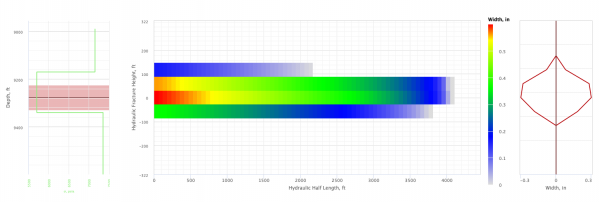

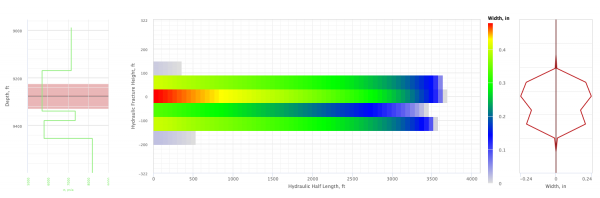

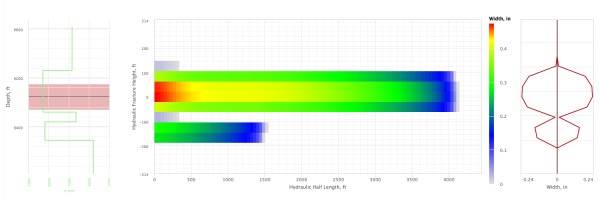

The fracture net pressure, half-length, width and height predicted by different simulators[1] are plotted below in dots. The overlapped onPlan fracture net pressure, half-length, width and height shown as lines.

Single-Layer cases 1 and 2 show good agreement between onPlan and paper results.

3-Layer and 5-Layer cases 3 - 6 show that onPlan generally predicts less height thus more length and less width.

These comparisons show that differences in calculated fracture lengths can be large, as much as a factor of three difference. Fracture heights, for the multi-layer cases, can differ by more than 50%. Net pressures also differ by a factor of two.— Warpinski et al [1]

onPlan Hydraulic Fracturing Models

The onPlan models from this study are available online at www.pengtools.com by the following links:

Warpinski Case 1 (Single-Layer 200cp)

Warpinski Case 1 (Single-Layer 200cp)

Warpinski Case 2 (Single-Layer K&n)

Warpinski Case 2 (Single-Layer K&n)

Warpinski Case 3 (3-Layer 200cp)

Warpinski Case 3 (3-Layer 200cp)

Warpinski Case 4 (3-Layer K&n)

Warpinski Case 4 (3-Layer K&n)

Warpinski Case 5 (5-Layer 200cp)

Warpinski Case 5 (5-Layer 200cp)

Warpinski Case 6 (5-Layer K&n)

Warpinski Case 6 (5-Layer K&n)

Note that evaluation access is required to open the models. Please contact us to get evaluation access.

References

- ↑ 1.0 1.1 1.2 1.3 N.R., Warpinski; Z.A., Moschovidis; C.D., Parker; I.S., Abou-Sayed (1994). "Comparison Study of Hydraulic Fracturing Models—Test Case: GRI Staged Field Experiment No. 3 (includes associated paper 28158 )" (SPE-25890-PA). Society of Petroleum Engineers.