Hydraulic Fracturing Design Optimization - Bakken Case Study

Contents

Hydraulic Fracturing Design Optimization - Bakken Case Study

The case study is prepared to illustrate the unified approach to optimize the design of multiple transverse fractures in a horizontal well using the optiFracMS software.

The goal of the study is to optimize a fracturing design for a Bakken formation.

Two fracture design cases were considered:

- Operating company fracture design based on a Big Data application

- Optimized fracturing design based on the Type Curves

For the both cases a production forecast was calculated and cumulative oil production was compared.

Optimized fracture design case predicts 61% more cumulative oil in the first year of well production.

Inputs

The following inputs are used in both fracture design cases.

Fracturing Design Parameters |

Fracture Production Forecast Parameters | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

Hydraulic Fracturing Design Cases

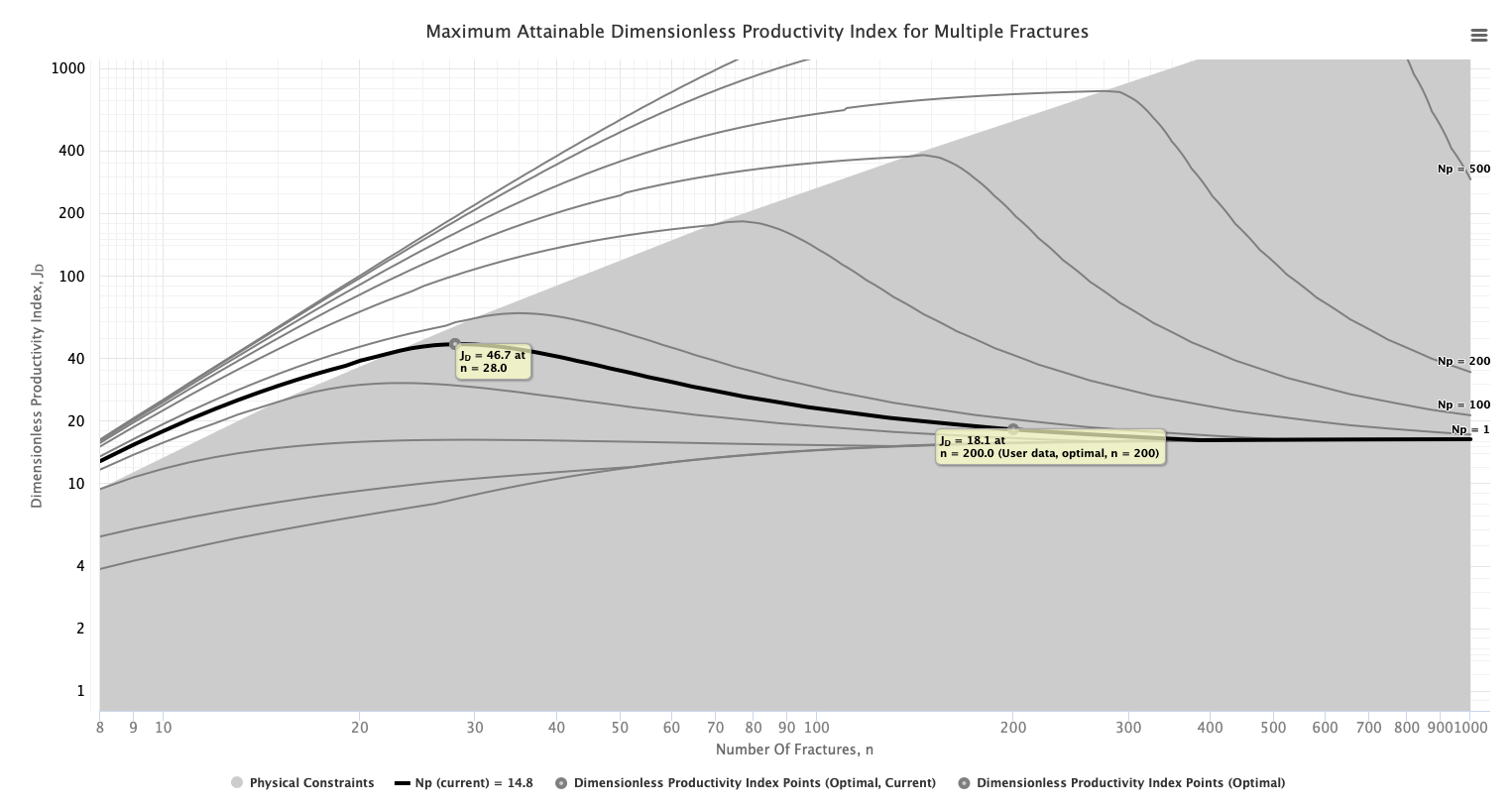

| Parameters | Big Data | Type Curves |

|---|---|---|

| Proppant number | 14.8 | 14.8 |

| Dimensionless productivity index, JD | 18.1 | 46.7 |

| Number of fractures, n | 200 | 28 |

| Dimensionless fracture conductivity, CfD | 60 | 8 |

| Fracture half length, xf, ft | 64 | 455 |

| Fracture width, wf, in | 0.032 | 0.032 |

| Fracture penetration, Ix | 0.1 | 0.7 |

Operating company design - Big Data

The Bakken Big Data study on the area compiled by the company petroleum engineers suggests an optimum completion design being 30 stages with 10 clusters per stage. Based on working experience, engineers estimate to get about 200 fractures as a result of the well stimulation.

Design agrees with the established within the company design practice of increasing the reservoir contact by adding more fractures to increase the oil rate.

Optimized fracturing design - Type Curves and optiFracMS

optiFracMS online petroleum engineering software at www.pengtools.com was run to optimize the fracture design[1].

The resulted design calculates the optimum number of fractures to be 28.

Note that optiFracMS was also used to calculate the design parameters (JD, CfD, xf, wf, Ix) of the Big Data design based on number of fractures of 200.

The model of the case study is available for review online at www.pengtools.com.

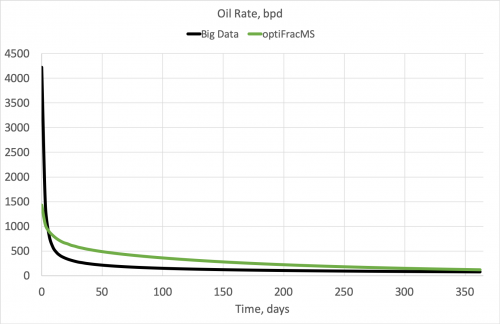

Hydraulic Fracturing Production Forecast

Both cases were simulated using the analytical model by Brown et al. [2] using the commercial software IHS Harmony.

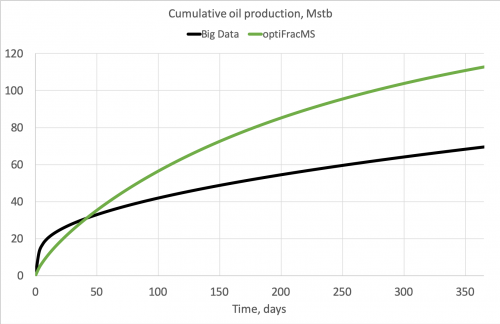

1 year production forecasts were compared as a result:

| Parameters | Big Data | optiFracMS |

|---|---|---|

| Cumulative oil production in 1 year, Mstb | 70 | 113 |

Bakken oil rate fracturing forecast

Bakken cumulative oil rate fracturing forecast

Bakken Case Study Discussion and Conclusions

The main conclusion

Optimized fracture design case predicts 61% more cumulative oil in the first year of well production.

Discussion

- The number of fractures was optimized from 200 to 28, which resulted in increase of the fractures half lengths from 64 to 455 ft, which increased the reservoir stimulation area and recovery.

- The Big data case produces high conductivity fractures (CfD =60 vs 8) with short fracture half lengths (xf = 64 vs 455 ft). This results in high initial rate which is rapidly declines due to lack of the reservoir contact area. The fracture underperforms.

- Make sure that technical optimum performance data is represented in your Big Data range. Otherwise care should be taken when applying the Big Data. If the data range is represented with the poor performance data only, the result will be the poor performance average.

References

- ↑ Guk, Vyacheslav; Tuzovskiy, Mikhail; Wolcott, Don; Mach, Joe (June 2019). "Optimizing Number of Fractures in Horizontal Well"

. SPE Journal. Society of Petroleum Engineers. 24 (03).

. SPE Journal. Society of Petroleum Engineers. 24 (03).

- ↑ Brown, Margaret; Ozkan, Erdal; Raghavan, Rajagopal; Kazemi, Hossein (December 2011). "Practical Solutions for Pressure-Transient Responses of Fractured Horizontal Wells in Unconventional Shale Reservoirs"

. SPE Reservoir Evaluation & Engineering. Society of Petroleum Engineers. 24 (06).

. SPE Reservoir Evaluation & Engineering. Society of Petroleum Engineers. 24 (06).