Category: OnPlan

Contents

Brief

onPlan is a fracture simulation tool for designing a hydraulic fracture treatment.

onPlan is developed under cooperation agreement between pengtools and Moscow Institute of Physics and Technology Oil&Gas Center LLC.

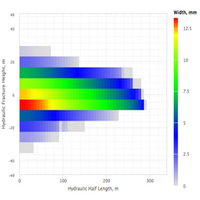

onPlan utilizes the Planar3D class model with advanced numerical optimization which allows to achieve high accuracy in predicting fracture geometry and fast simulation time.

onPlan integrates the Unified Fracture Design[1] concept which enables comparison of the designed frac geometry with the optimal one to maximize the performance of the fractured well.

onPlan is available online at www.pengtools.com.

Typical applications

- Simulation of the single vertical well fractures in low stress contrast environments with a high risk of fracture breakthrough into overlying gas or underlying water

- Optimization of hydraulic fracturing with Unified Fracture Design[1]

- Understanding post-fracturing production performance

- Sensitivity studies

Main features

- Fracture design charts: height, width, length, pressure vs time; height vs width; width vs length; height vs length. All showing propped and hydraulic values.

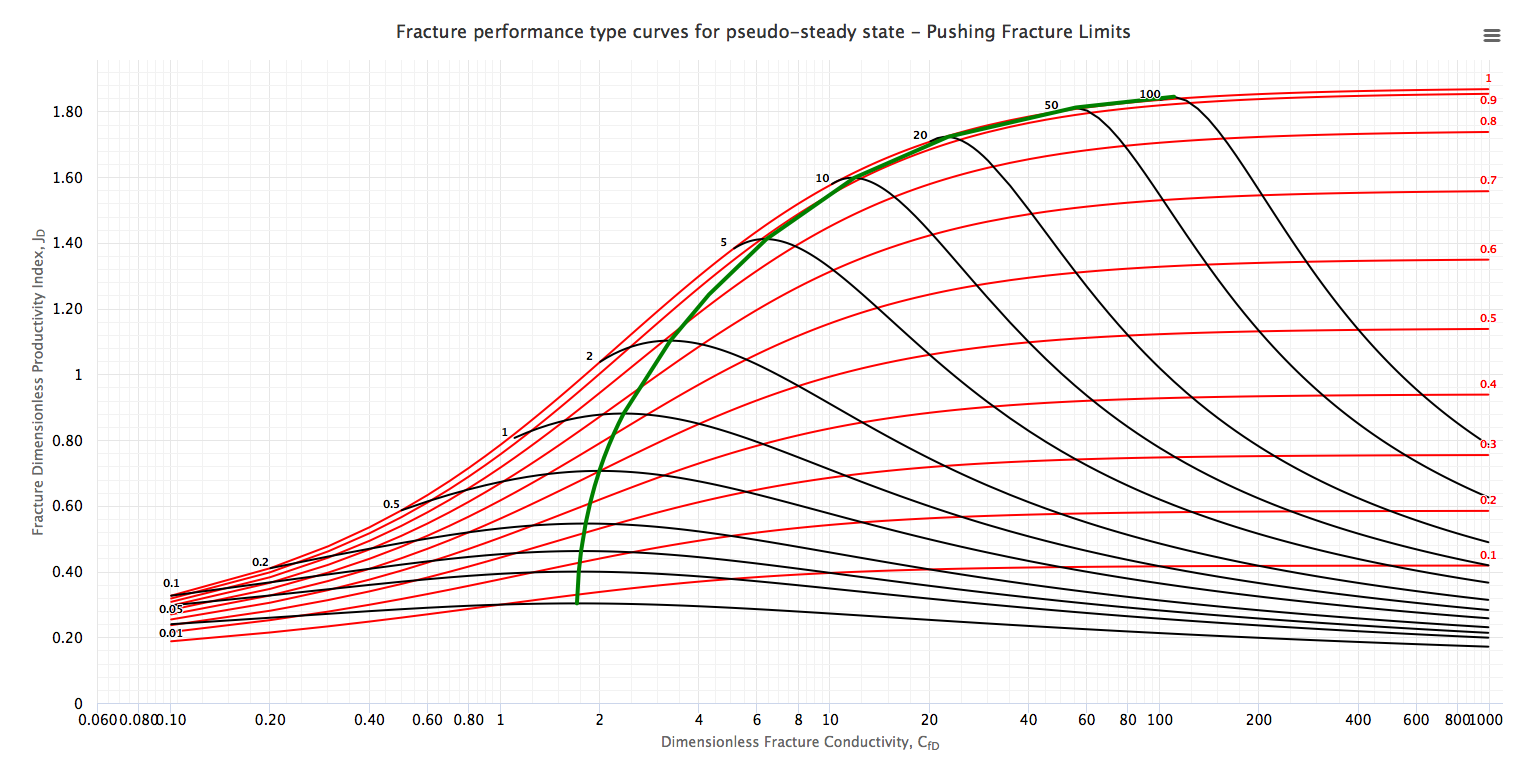

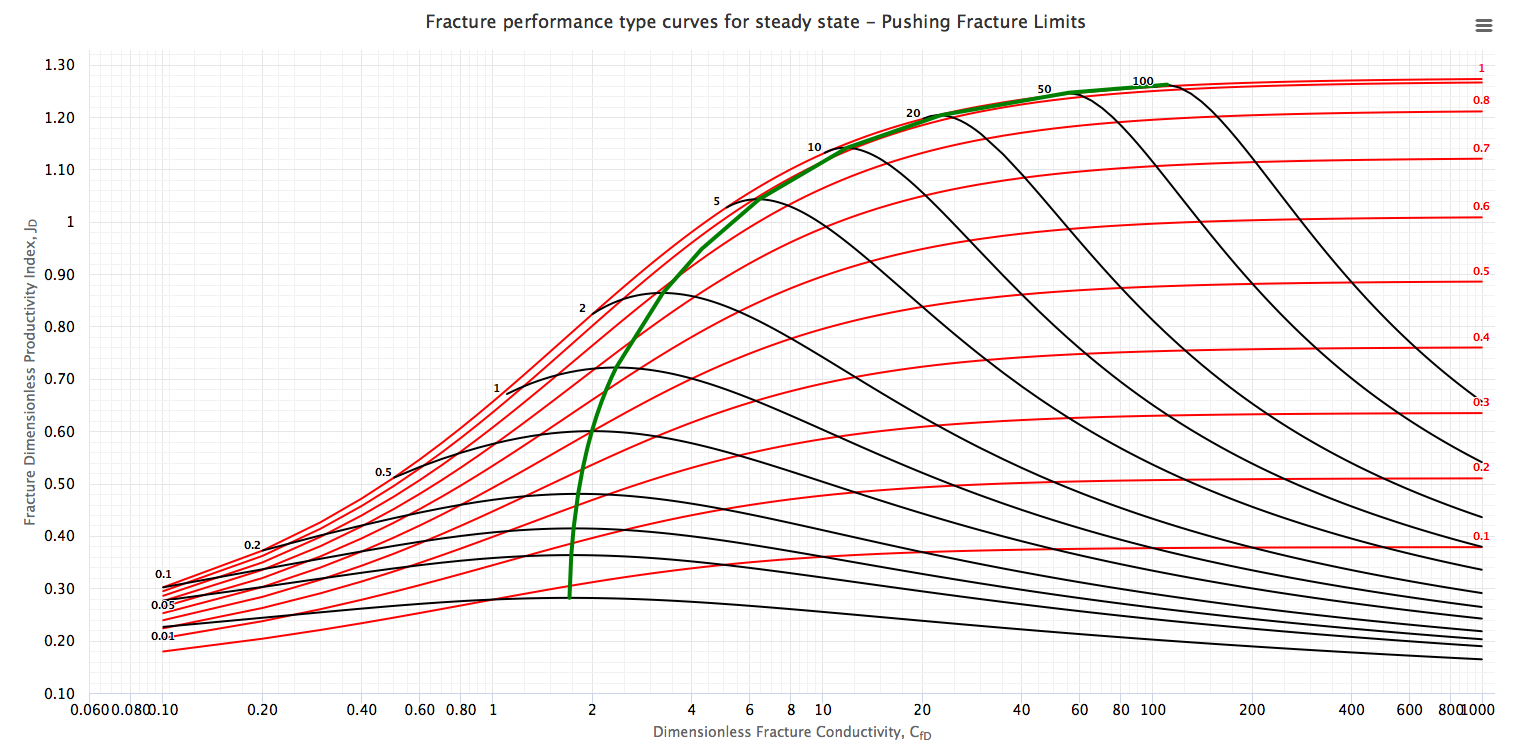

- Fracture design Type Curves (Plot of JD as a function of CfD using Ix and Np as parameter) showing the current fracture design and the optimal one.

- Design Optimization Curve which corresponds to the maximum JD values for different Np.

- Design Optimum Point at which JD is maximized for the given proppant, fracture and reservoir parameters.

- Physical constraints envelope.

- Proppant catalog with predefined proppant properties.

- Users reference data for benchmarking vs actual.

- Switch between Metric and Field units

- Save/load models to the files and to the user’s cloud

- Share models to the public cloud or by using model’s link

- Export pdf report containing input parameters, calculated values and plots

- Continue your work from where you stopped: last saved model will be automatically opened

- Download the chart as an image or data and print (upper-right corner chart’s button)

- Export results table to Excel or other application

Math & Physics

Basic equations of Planar3D model:

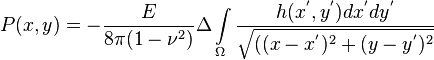

( 1 ) - elastic reaction of formation

( 1 ) - elastic reaction of formation

,

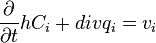

,  ( 2 ) - 2D equation of multifluid flow and proppant transport

( 2 ) - 2D equation of multifluid flow and proppant transport

The model accounts for the effect of proppant bridging and gravitational setting.

Type Curves

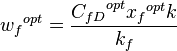

The Type Curves shows the dimensionless productivity index, JD, at steady and pseudo-steady state as function of CfD, using Ix as parameter (red curves) and overlapping with the type curve with Np as parameter (black curves).

The green curve along the maximum points for different Np values is “Design Optimization Curve”[2]. This curve represents the target of the designs of the fracture treatments in a dimensionless form.

Type Curves were obtained, through seven hundred runs with a numerical simulator, modeling a fractured well in a closed square reservoir [2]. For infinite and finite fracture conductivities, the shape factors, CA, can be calculated if the PD is known for a specific value of Ix. The PD value obtained by numerical simulations. After knowing CA (which would be a function of Ix), f-function values can be calculated if PD is known for a specific dimensionless fracture conductivity CfD and fracture penetration Ix.

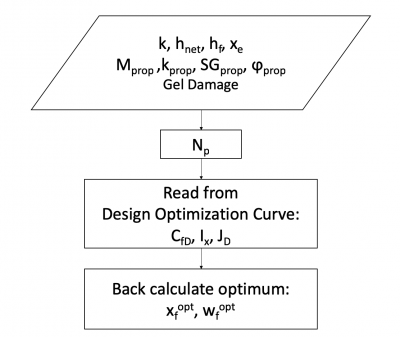

Flow Diagram

Workflow

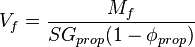

1. Calculate the Np:

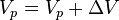

the volume of the reservoir

the volume of the reservoir

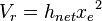

the fracture permeability

the fracture permeability

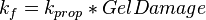

the proppant mass in the pay zone

the proppant mass in the pay zone

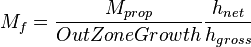

the fracture volume in the pay zone

the fracture volume in the pay zone

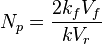

the proppant number

the proppant number

2. Read CfDopt, Ixopt, JDopt from the Design Optimization Curve of the Type Curve

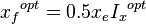

3. Calculate optimum fracture half-length and width:

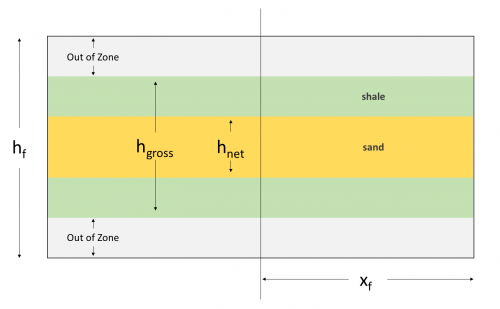

the fracture height

the fracture height

Physical Constraints

It is important to mention that the Design Optimization Curve could give unrealistic fracture geometry depending on the reservoir permeability, reservoir mechanical properties and target Np. The two most common scenarios are [2]:

- The required net pressure for the fracture geometry is too high - “maximum net pressure curve”,

- Fracture width is too small (fracture too narrow) - “minimum width curve”.

The area between the “minimum width curve” and the “maximum net pressure curve” is the “working area” (highlighted in yellow) of the whole type curve for the specific rock mechanical properties, reservoir and proppant properties used. Any fracture design for this specific case should be located on the “optimum design curve” anywhere in this working area depending on the desired Np[2].

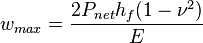

Maximum net pressure

The maximum net pressure during the fracturing treatment should provide a surface pressure less than a certain value (which is surface pressure operational limit) [2].

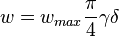

Minimum fracture width

Fracture propped width should be greater than N times mean proppant diameter (to provide at least N proppant layers in the fracture after closure)[2]. N=3 in the optiFrac.

Nomenclature

= dimensionless fracture conductivity, dimensionless

= dimensionless fracture conductivity, dimensionless = shape factor, dimensionless

= shape factor, dimensionless = Young's Modulus, psia

= Young's Modulus, psia = f-function, dimensionless

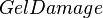

= f-function, dimensionless = proppant permeability reduction due to gel damage, %

= proppant permeability reduction due to gel damage, % = height, ft

= height, ft = penetration ratio, dimensionless

= penetration ratio, dimensionless = dimensionless productivity index, dimensionless

= dimensionless productivity index, dimensionless = permeability, md

= permeability, md = mass, lbm

= mass, lbm = dimensionless proppant number, dimensionless

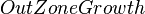

= dimensionless proppant number, dimensionless = out of the zone growth, 0% - no growth, 50% - half of proppant is out of zone

= out of the zone growth, 0% - no growth, 50% - half of proppant is out of zone = dimensionless pressure (based on average pressure), dimensionless

= dimensionless pressure (based on average pressure), dimensionless = net pressure, psia

= net pressure, psia = specific gravity, dimensionless

= specific gravity, dimensionless = volume, ft3

= volume, ft3 = width, ft

= width, ft = drainage area, ft2

= drainage area, ft2 = fracture half-length, ft

= fracture half-length, ft

Greek symbols

= dry to wet width ratio at the end of pumping, usually 0.5-0.7

= dry to wet width ratio at the end of pumping, usually 0.5-0.7 = geometric factor in vertical direction, 0.75 for PKN model, 1 for KGD model

= geometric factor in vertical direction, 0.75 for PKN model, 1 for KGD model = Poisson's ratio, dimensionless

= Poisson's ratio, dimensionless  = porosity, fraction

= porosity, fraction = 3.1415

= 3.1415

Superscripts

- opt = optimal

- pss = pseudo-steady state

- ss = steady state

Subscripts

- e = external

- f = fracture

- gross = gross

- max = maximum

- net = net

- prop = proppant

- r = reservoir

References

- ↑ 1.0 1.1 Economides, Michael J.; Oligney, Ronald; Valko, Peter (2002). Unified Fracture Design: Bridging the Gap Between Theory and Practice. Alvin, Texas: Orsa Press.

- ↑ 2.0 2.1 2.2 2.3 2.4 2.5 Rueda, J.I.; Mach, J.; Wolcott, D. (2004). "Pushing Fracturing Limits to Maximize Producibility in Turbidite Formations in Russia"

(SPE-91760-MS). Society of Petroleum Engineers.

(SPE-91760-MS). Society of Petroleum Engineers.

Pages in category "OnPlan"

The following 4 pages are in this category, out of 4 total.