Difference between revisions of "FracDesign Comparison Study 1 Warpinski"

(→fracDesign Models) |

|||

| (12 intermediate revisions by the same user not shown) | |||

| Line 10: | Line 10: | ||

{{Quote| text = This study is a comparison of hydraulic fracture models run using test data from the GRI Staged Field Experiment No. 3. Models compared include 2D, pseudo-3D, and 3D codes, run on up to eight different cases. Documented in this comparison are the differences in length, height, width, pressure, and efficiency. The purpose of this study is to provide the completions engineer with a practical comparison of the available models so that rational decisions can be made as to which model is optimal for a given application. | source = Warpinski et al <ref name= Warpinski />}} | {{Quote| text = This study is a comparison of hydraulic fracture models run using test data from the GRI Staged Field Experiment No. 3. Models compared include 2D, pseudo-3D, and 3D codes, run on up to eight different cases. Documented in this comparison are the differences in length, height, width, pressure, and efficiency. The purpose of this study is to provide the completions engineer with a practical comparison of the available models so that rational decisions can be made as to which model is optimal for a given application. | source = Warpinski et al <ref name= Warpinski />}} | ||

| − | ===Simulators=== | + | ===Hydraulic Fracture Simulators=== |

Planar 3D models: | Planar 3D models: | ||

| Line 42: | Line 42: | ||

<tr><td>Fluid Properties </td><td> </td><td> </td><td> </td><td> </td></tr> | <tr><td>Fluid Properties </td><td> </td><td> </td><td> </td><td> </td></tr> | ||

<tr><td>Viscosity, cP</td><td>200</td><td> </td><td>200</td><td> </td></tr> | <tr><td>Viscosity, cP</td><td>200</td><td> </td><td>200</td><td> </td></tr> | ||

| − | <tr><td>K, (lbf-sec^n)/ft^2</td><td> </td><td>0. | + | <tr><td>K, (lbf-sec^n)/ft^2</td><td> </td><td>0.06</td><td> </td><td>0.06</td></tr> |

| − | <tr><td>n</td><td> </td><td>0. | + | <tr><td>n</td><td> </td><td>0.5</td><td> </td><td>0.5</td></tr> |

<tr><td>Leak-off, ft/min^0.5 </td><td>0.00025</td><td>0.00025</td><td>0.00025</td><td>0.00025</td></tr> | <tr><td>Leak-off, ft/min^0.5 </td><td>0.00025</td><td>0.00025</td><td>0.00025</td><td>0.00025</td></tr> | ||

<tr><td>Spurt loss, gal/ft^2</td><td>0</td><td>0</td><td>0</td><td>0</td></tr> | <tr><td>Spurt loss, gal/ft^2</td><td>0</td><td>0</td><td>0</td><td>0</td></tr> | ||

| Line 72: | Line 72: | ||

===fracDesign Models=== | ===fracDesign Models=== | ||

| − | The [[:category:fracDesign| fracDesign]] models from this study can be | + | The [[:category:fracDesign| fracDesign]] models from this study are publicly available online at [https://www.pengtools.com www.pengtools.com] and can be opened through the links below: |

| − | [https://www.pengtools.com/fracDesign?paramsToken=5b20b216fcf9bb1ac9aed5d04620d1a9 Case 1] | + | [https://www.pengtools.com/fracDesign?paramsToken=5b20b216fcf9bb1ac9aed5d04620d1a9 Warpinski Case 1] |

| − | [https://www.pengtools.com/fracDesign?paramsToken=2e3113151dd21bcff4b544467f6b6633 Case 2] | + | [https://www.pengtools.com/fracDesign?paramsToken=2e3113151dd21bcff4b544467f6b6633 Warpinski Case 2] |

| − | [https://www.pengtools.com/fracDesign?paramsToken=b6bb9bc0aaafa75624901216e3013880 Case 3] | + | [https://www.pengtools.com/fracDesign?paramsToken=b6bb9bc0aaafa75624901216e3013880 Warpinski Case 3] |

| − | [https://www.pengtools.com/fracDesign?paramsToken=2b30a86ab8877577d42e3bd7377313d0 Case 4] | + | [https://www.pengtools.com/fracDesign?paramsToken=2b30a86ab8877577d42e3bd7377313d0 Warpinski Case 4] |

==References== | ==References== | ||

| Line 99: | Line 99: | ||

[[Category:fracDesign]] | [[Category:fracDesign]] | ||

| + | [[Category:pengtools]] | ||

| + | |||

| + | {{#seo: | ||

| + | |title=Hydraulic Fracturing Case Study Warpinski vs fracDesign | ||

| + | |titlemode= replace | ||

| + | |keywords=hydraulic fracturing, comparison study, hydraulic fracturing formulas | ||

| + | |description=Hydraulic fracturing design software fracDesign vs Warpinski SPE paper 25890: Comparison Study of Hydraulic Fracturing Models. | ||

| + | }} | ||

Latest revision as of 08:26, 15 November 2019

Contents

Brief

The case study is based on Warpinski [1] paper published in 1994.

The fracDesign calculates 4 cases described in the paper and shows good agreement in results.

Inputs

Paper Summary

This study is a comparison of hydraulic fracture models run using test data from the GRI Staged Field Experiment No. 3. Models compared include 2D, pseudo-3D, and 3D codes, run on up to eight different cases. Documented in this comparison are the differences in length, height, width, pressure, and efficiency. The purpose of this study is to provide the completions engineer with a practical comparison of the available models so that rational decisions can be made as to which model is optimal for a given application.— Warpinski et al [1]

Hydraulic Fracture Simulators

Planar 3D models:

- TerraFrac of TerraTek Inc.

- HYFRAC3D by S.H. Advani of Lehigh U. - Planar 3D model

- GOHFER by by Marathon Oil Co. - a unique finite-difference simulator

Planar pseudo-3D models:

- STIMPLAN of NSI Inc.

- ENERFRAC of Shell

- TRIFRAC of S.A. Holditch & Assocs. Inc.

- FRACPRO of Reservoir Engineering Systems (RES) Inc.

- MFRAC-II of Meyer& Assocs.

Classic Perkins-Kern-Nordgren (PKN) and Geertsma-deKlerk (GDK) model:

- PROP of Halliburton

- Chevron 2D model

- Conoco 2D model

- Shell 2D model

- pseudo-3D models run in constant-height mode

Cases

| CASE | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Formation Properties | ||||

| Young's modulus, psi | 8.50E+06 | 8.50E+06 | 8.50E+06 | 8.50E+06 |

| Poisson's ratio | 0.21 | 0.21 | 0.21 | 0.21 |

| In situ stress, psi | 5700 | 5700 | 5700 | 5700 |

| Fracture toughness, psi in^0.5 | 2000 | 2000 | 2000 | 2000 |

| Fluid Properties | ||||

| Viscosity, cP | 200 | 200 | ||

| K, (lbf-sec^n)/ft^2 | 0.06 | 0.06 | ||

| n | 0.5 | 0.5 | ||

| Leak-off, ft/min^0.5 | 0.00025 | 0.00025 | 0.00025 | 0.00025 |

| Spurt loss, gal/ft^2 | 0 | 0 | 0 | 0 |

| Other Data | ||||

| Model | PKN | PKN | KGD | KGD |

| Pumping rate, bbl/min | 50 | 50 | 50 | 50 |

| Pumping volume, bbl | 10000 | 10000 | 10000 | 10000 |

| Pupming time, min | 200 | 200 | 200 | 200 |

| Perforated interval, ft | 170* | 170* | 170* | 170* |

| Pay-zone thickness, ft | 170 | 170 | 170 | 170 |

| Depth, ft | 9170-9340 | 9170-9340 | 9170-9340 | 9170-9340 |

* - The PKN and GDK cases were run with a constant height (2-D) set at 170 ft (52 m).

Comparison

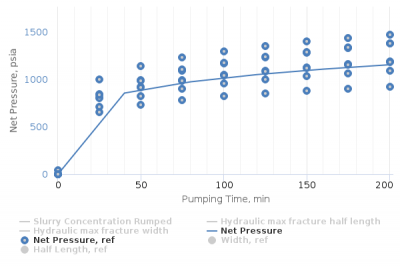

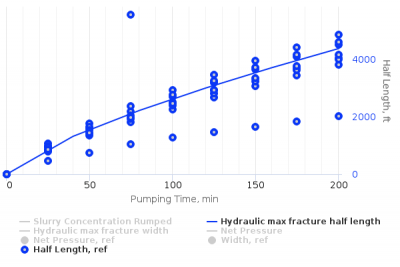

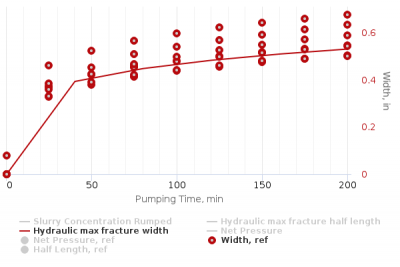

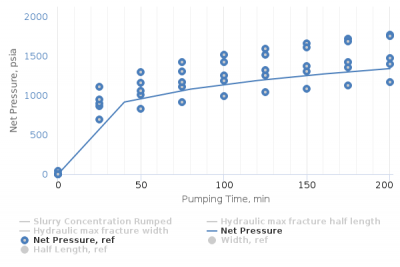

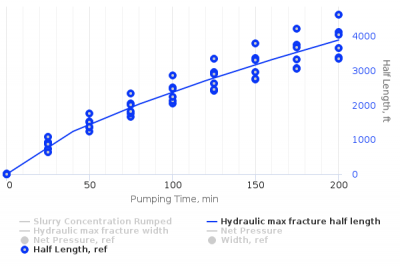

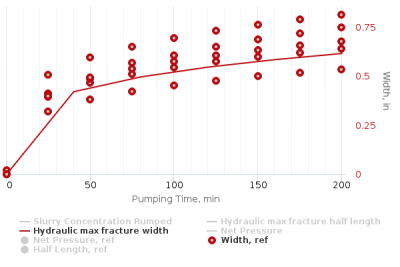

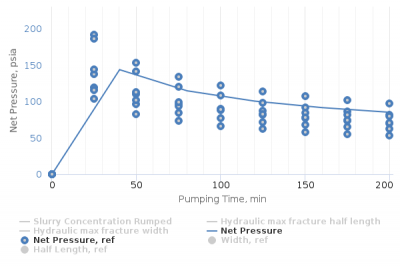

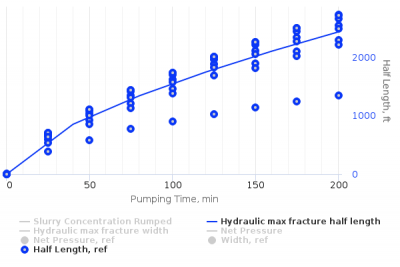

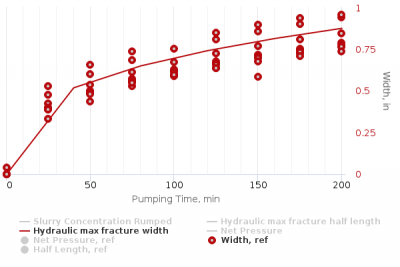

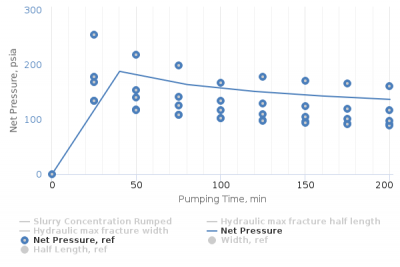

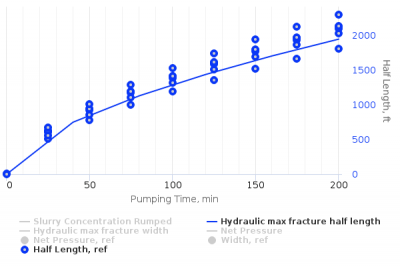

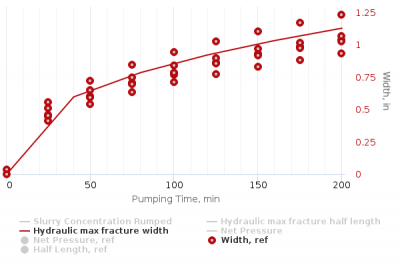

The fracture net pressure, half-length and width predicted by different simulators[1] are plotted below in dots. The overlapped fracDesign fracture net pressure, half-length and width shown as lines are in a good agreement with the simulation data.

fracDesign Models

The fracDesign models from this study are publicly available online at www.pengtools.com and can be opened through the links below:

References

- ↑ 1.0 1.1 1.2 N.R., Warpinski; Z.A., Moschovidis; C.D., Parker; I.S., Abou-Sayed (1994). "Comparison Study of Hydraulic Fracturing Models—Test Case: GRI Staged Field Experiment No. 3 (includes associated paper 28158 )" (SPE-25890-PA). Society of Petroleum Engineers.