Difference between revisions of "Category: OnPlan"

(→Main features) |

|||

| (39 intermediate revisions by the same user not shown) | |||

| Line 4: | Line 4: | ||

[[File:onPlan_i.png|thumb|right|200px|link=https://www.pengtools.com/onPlan|pengtools onPlan]] | [[File:onPlan_i.png|thumb|right|200px|link=https://www.pengtools.com/onPlan|pengtools onPlan]] | ||

| − | [[:Category:onPlan| onPlan]] is a fracture simulation | + | [[:Category:onPlan| onPlan]] is a hydraulic fracture simulation software for designing a hydraulic fracture treatment. |

| − | [[:Category:onPlan| onPlan]] is | + | [[:Category:onPlan| onPlan]] is released under cooperation agreement between [[:category:pengtools | pengtools]] and [https://mipt.ru/education/chair/applied_mechanics/ Moscow Institute of Physics and Technology Oil&Gas Center LLC]. |

[[:Category:onPlan| onPlan]] utilizes the Planar3D class model with advanced numerical optimization which allows to achieve high accuracy in predicting fracture geometry and fast simulation time. | [[:Category:onPlan| onPlan]] utilizes the Planar3D class model with advanced numerical optimization which allows to achieve high accuracy in predicting fracture geometry and fast simulation time. | ||

| Line 16: | Line 16: | ||

== Typical applications == | == Typical applications == | ||

| − | * Simulation of | + | * Simulation of a single vertical well fractures in low stress contrast environments with a high risk of fracture breakthrough into overlying gas or underlying water |

* Optimization of hydraulic fracturing with '''Unified Fracture Design'''<ref name=UFD2002/> | * Optimization of hydraulic fracturing with '''Unified Fracture Design'''<ref name=UFD2002/> | ||

* Understanding post-fracturing production performance | * Understanding post-fracturing production performance | ||

* Sensitivity studies | * Sensitivity studies | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

==Math & Physics== | ==Math & Physics== | ||

| Line 46: | Line 30: | ||

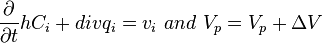

:<math>\frac{\partial}{\partial t} h C_i + div q_i = v_i\ and\ V_p = V_p + \Delta V</math> ( 2 ) - 2D equation of multifluid flow and proppant transport | :<math>\frac{\partial}{\partial t} h C_i + div q_i = v_i\ and\ V_p = V_p + \Delta V</math> ( 2 ) - 2D equation of multifluid flow and proppant transport | ||

| − | The model accounts for the effect of proppant bridging | + | The model accounts for the effect of proppant bridging, gravitational setting and multifluid flow. |

| − | The mathematical model is supplemented by rheological dependencies for coupling the flow of a fluid with a pressure gradient and equations for calculating | + | The mathematical model is supplemented by rheological dependencies for coupling the flow of a fluid with a pressure gradient and equations for calculating leak-off to the reservoir. |

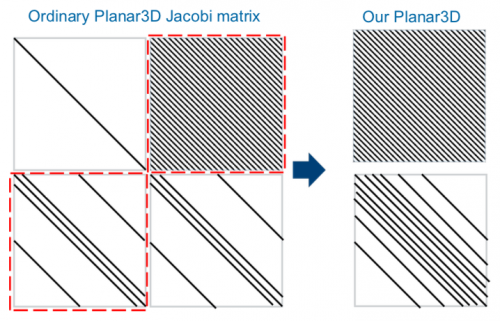

===Splitting by physical processes=== | ===Splitting by physical processes=== | ||

In usual numerical Planar3D implementation, Jacobi matrix includes parts that describe geomechanical and hydrodynamical processes. Splitting by physical processes allows to solve geomechanics and hydrodynamics separately. Splitting turns one linear system with dense matrix into two. Separate solving requires significantly less computation resources than solving whole system. | In usual numerical Planar3D implementation, Jacobi matrix includes parts that describe geomechanical and hydrodynamical processes. Splitting by physical processes allows to solve geomechanics and hydrodynamics separately. Splitting turns one linear system with dense matrix into two. Separate solving requires significantly less computation resources than solving whole system. | ||

| − | == | + | ==MIPT developers== |

| − | [ | + | [https://mipt.ru/english/ Moscow Institute of Physics and Technology] |

| − | + | [https://mipt.ru/science/labs/laboratoriya-modelirovaniya-mekhanicheskikh-sistem-i-protsessov/ Laboratory of Modeling of Mechanical Systems and Processes] | |

| − | [[File: | + | [[File:Natalia Zavialova.jpg|300px| Natalia Zavialova]] |

| − | + | [[File:Ilia Perepechkin.jpg|300px| Ilia Perepechkin]] | |

| − | + | == Comparison Studies == | |

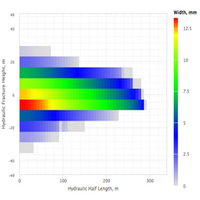

| − | : | + | [[File:Weng Case B.png|300px| Weng Case B]] |

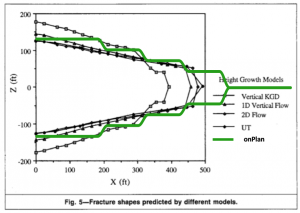

| − | + | 1. [[OnPlan Comparison Study 1 Weng]]. The onPlan calculates 12 cases described in the paper and shows reasonable agreement in results. | |

| − | : | + | [[File:Warpinski Case 5.png|600px| Warpinski Case 5 (5-Layer 200cp)]] |

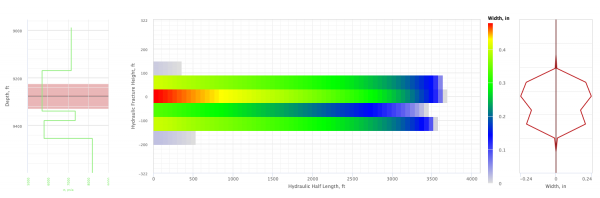

| − | + | 2. [[OnPlan Comparison Study 2 Warpinski]]. | |

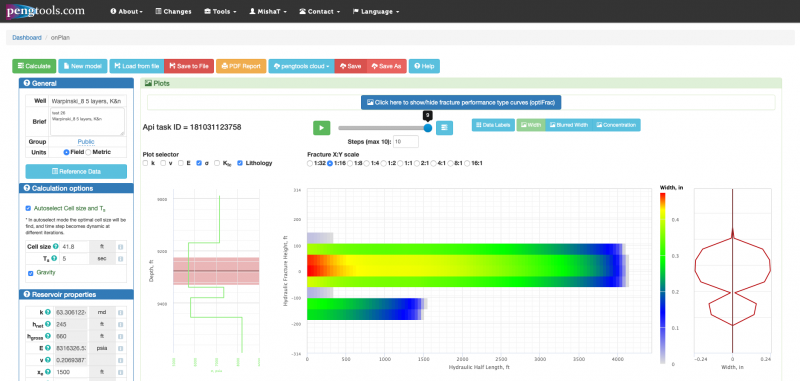

| − | + | == Main page screenshot == | |

| − | + | [[File:onPlan main page.png|800px| onPlan main page]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | == Main features == | |

| − | + | * Fracture design charts: height, width, length, pressure vs time; height vs width; width vs length; height vs length. All showing propped and hydraulic values. | |

| − | + | * Fracture design Type Curves (Plot of '''J<sub>D</sub>''' as a function of '''C<sub>fD</sub>''' using '''I<sub>x</sub>''' and '''N<sub>p</sub>''' as parameter) showing the current fracture design and the optimal one. | |

| − | + | * Design Optimization Curve which corresponds to the maximum '''J<sub>D</sub>''' values for different '''N<sub>p</sub>'''. | |

| − | + | * Design Optimum Point at which '''J<sub>D</sub>''' is maximized for the given proppant, fracture and reservoir parameters. | |

| − | + | * Physical constraints envelope. | |

| − | + | * [[Hydraulic fracturing proppant catalog]] with predefined proppant properties. | |

| − | + | * Users reference data for benchmarking vs actual. | |

| − | + | * Switch between Metric and Field units | |

| − | + | * Save/load models to the files and to the user’s cloud | |

| − | + | * Share models to the public cloud or by using model’s link | |

| − | + | * Export pdf report containing input parameters, calculated values and plots | |

| − | + | * Continue your work from where you stopped: last saved model will be automatically opened | |

| − | + | * Download the chart as an image or data and print (upper-right corner chart’s button) | |

| − | + | * Export results table to Excel or other application | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | : | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

== References == | == References == | ||

<references> | <references> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<ref name=UFD2002>{{cite book | <ref name=UFD2002>{{cite book | ||

|last1= Economides |first1= Michael J. | |last1= Economides |first1= Michael J. | ||

| Line 173: | Line 92: | ||

</references> | </references> | ||

[[Category:pengtools]] | [[Category:pengtools]] | ||

| + | |||

| + | {{#seo: | ||

| + | |title=Hydraulic Fracturing Simulation Software | ||

| + | |titlemode= replace | ||

| + | |keywords= simulator, hydraulic fracturing, hydraulic fracturing simulation software, hydraulic fracturing formulas, hydraulic fracturing proppant, hydraulic fracturing liquids, petroleum engineering, planar 3D | ||

| + | |description=onPlan is a planar 3D hydraulic fracture simulation software for designing a hydraulic fracture treatment in pengtools. | ||

| + | }} | ||

Latest revision as of 06:30, 10 December 2018

Contents

Brief

onPlan is a hydraulic fracture simulation software for designing a hydraulic fracture treatment.

onPlan is released under cooperation agreement between pengtools and Moscow Institute of Physics and Technology Oil&Gas Center LLC.

onPlan utilizes the Planar3D class model with advanced numerical optimization which allows to achieve high accuracy in predicting fracture geometry and fast simulation time.

onPlan integrates the Unified Fracture Design[1] concept which enables comparison of the designed frac geometry with the optimal one to maximize the performance of the fractured well.

onPlan is available online at www.pengtools.com.

Typical applications

- Simulation of a single vertical well fractures in low stress contrast environments with a high risk of fracture breakthrough into overlying gas or underlying water

- Optimization of hydraulic fracturing with Unified Fracture Design[1]

- Understanding post-fracturing production performance

- Sensitivity studies

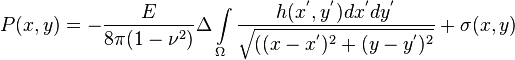

Math & Physics

Basic equations of Planar3D model:

( 1 ) - elastic reaction of formation

( 1 ) - elastic reaction of formation

( 2 ) - 2D equation of multifluid flow and proppant transport

( 2 ) - 2D equation of multifluid flow and proppant transport

The model accounts for the effect of proppant bridging, gravitational setting and multifluid flow.

The mathematical model is supplemented by rheological dependencies for coupling the flow of a fluid with a pressure gradient and equations for calculating leak-off to the reservoir.

Splitting by physical processes

In usual numerical Planar3D implementation, Jacobi matrix includes parts that describe geomechanical and hydrodynamical processes. Splitting by physical processes allows to solve geomechanics and hydrodynamics separately. Splitting turns one linear system with dense matrix into two. Separate solving requires significantly less computation resources than solving whole system.

MIPT developers

Moscow Institute of Physics and Technology

Laboratory of Modeling of Mechanical Systems and Processes

Comparison Studies

1. OnPlan Comparison Study 1 Weng. The onPlan calculates 12 cases described in the paper and shows reasonable agreement in results.

2. OnPlan Comparison Study 2 Warpinski.

Main page screenshot

Main features

- Fracture design charts: height, width, length, pressure vs time; height vs width; width vs length; height vs length. All showing propped and hydraulic values.

- Fracture design Type Curves (Plot of JD as a function of CfD using Ix and Np as parameter) showing the current fracture design and the optimal one.

- Design Optimization Curve which corresponds to the maximum JD values for different Np.

- Design Optimum Point at which JD is maximized for the given proppant, fracture and reservoir parameters.

- Physical constraints envelope.

- Hydraulic fracturing proppant catalog with predefined proppant properties.

- Users reference data for benchmarking vs actual.

- Switch between Metric and Field units

- Save/load models to the files and to the user’s cloud

- Share models to the public cloud or by using model’s link

- Export pdf report containing input parameters, calculated values and plots

- Continue your work from where you stopped: last saved model will be automatically opened

- Download the chart as an image or data and print (upper-right corner chart’s button)

- Export results table to Excel or other application

References

- ↑ 1.0 1.1 Economides, Michael J.; Oligney, Ronald; Valko, Peter (2002). Unified Fracture Design: Bridging the Gap Between Theory and Practice. Alvin, Texas: Orsa Press.

Pages in category "OnPlan"

The following 4 pages are in this category, out of 4 total.