Difference between revisions of "Fanning correlation"

From wiki.pengtools.com

| (14 intermediate revisions by the same user not shown) | |||

| Line 2: | Line 2: | ||

== Brief == | == Brief == | ||

| − | The [[Fanning correlation]] is the name used to refer to the calculation of the hydrostatic pressure difference and the friction pressure loss for the dry gas. | + | The [[Fanning correlation]] is the name used to refer to the calculation of the hydrostatic pressure difference and the friction pressure loss for the dry gas flow. |

| − | [[Fanning correlation]] is the default [[VLP]] correlation for the '''dry gas wells''' in the [[: | + | [[Fanning correlation]] is the default [[VLP]] correlation for the '''dry gas wells''' in the [[PQplot]]. |

| + | |||

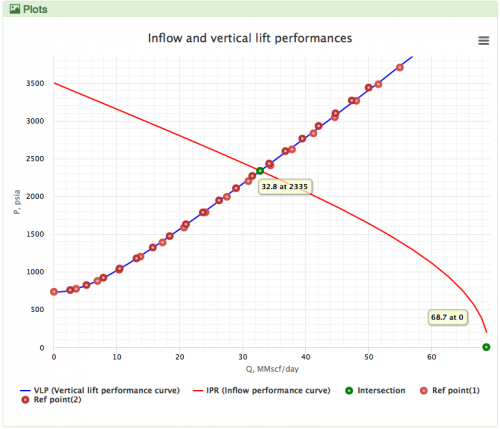

| + | [[File: Fanning.png|thumb|500px|link=https://www.pengtools.com/pqPlot?paramsToken=49064d9f7a281b1810e28e8bee255fb2|Fanning in PQplot Vs Prosper & Kappa |right]] | ||

== Math & Physics == | == Math & Physics == | ||

| Line 24: | Line 26: | ||

Why [[Fanning correlation]] ? | Why [[Fanning correlation]] ? | ||

| − | {{Quote| text = | + | {{Quote| text = [[Fanning correlation]] actually is not a correlation, it's the fully explicit workflow to define the pressure drop. | source = www.pengtools.com}} |

== Nomenclature == | == Nomenclature == | ||

| Line 35: | Line 37: | ||

:<math> T </math> = temperature, °R or °K, follow the subscript | :<math> T </math> = temperature, °R or °K, follow the subscript | ||

:<math> v </math> = velocity, ft/sec | :<math> v </math> = velocity, ft/sec | ||

| − | |||

:<math> z </math> = gas compressibility factor, dimensionless | :<math> z </math> = gas compressibility factor, dimensionless | ||

| Line 41: | Line 42: | ||

:<math> \varepsilon </math> = absolute roughness, ft | :<math> \varepsilon </math> = absolute roughness, ft | ||

| − | |||

:<math> \mu </math> = viscosity, cp | :<math> \mu </math> = viscosity, cp | ||

:<math> \rho </math> = density, lb<sub>m</sub>/ft<sup>3</sup> | :<math> \rho </math> = density, lb<sub>m</sub>/ft<sup>3</sup> | ||

| − | |||

| − | |||

===Subscripts=== | ===Subscripts=== | ||

| Line 52: | Line 50: | ||

K = °K<BR/> | K = °K<BR/> | ||

L = liquid<BR/> | L = liquid<BR/> | ||

| − | |||

| − | |||

R = °R<BR/> | R = °R<BR/> | ||

| − | |||

SG = superficial gas<BR/> | SG = superficial gas<BR/> | ||

| − | |||

== References == | == References == | ||

<references> | <references> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<ref name=Colebrook>{{cite journal | <ref name=Colebrook>{{cite journal | ||

| Line 94: | Line 80: | ||

|url-access=subscription | |url-access=subscription | ||

}} </ref> | }} </ref> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<ref name= Lyons>{{cite book | <ref name= Lyons>{{cite book | ||

| Line 113: | Line 89: | ||

|place=Houston, TX | |place=Houston, TX | ||

|isbn=0-88415-643-5 | |isbn=0-88415-643-5 | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

}}</ref> | }}</ref> | ||

| Line 128: | Line 94: | ||

[[Category:pengtools]] | [[Category:pengtools]] | ||

| − | [[Category: | + | [[Category:PQplot]] |

| + | [[Category:sPipe] | ||

| + | |||

| + | {{#seo: | ||

| + | |title=Fanning correlation dry gas flow | ||

| + | |titlemode= replace | ||

| + | |keywords=Fanning correlation | ||

| + | |description=Fanning correlation is the name used to refer to the calculation of the hydrostatic pressure difference and the friction pressure loss for the dry gas flow. | ||

| + | }} | ||

Latest revision as of 09:45, 6 December 2018

Contents

Brief

The Fanning correlation is the name used to refer to the calculation of the hydrostatic pressure difference and the friction pressure loss for the dry gas flow.

Fanning correlation is the default VLP correlation for the dry gas wells in the PQplot.

Math & Physics

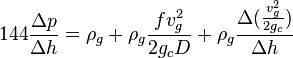

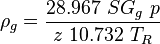

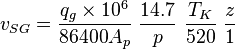

Following the law of conservation of energy the basic steady state flow equation is:

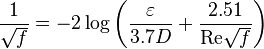

Colebrook–White [1] equation for the Darcy's friction factor:

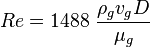

Reynolds number:

Discussion

Why Fanning correlation ?

Fanning correlation actually is not a correlation, it's the fully explicit workflow to define the pressure drop.— www.pengtools.com

Nomenclature

= depth, ft

= depth, ft = friction factor, dimensionless

= friction factor, dimensionless = pressure, psia

= pressure, psia = Reynolds number, dimensionless

= Reynolds number, dimensionless = specific gravity, dimensionless

= specific gravity, dimensionless = temperature, °R or °K, follow the subscript

= temperature, °R or °K, follow the subscript = velocity, ft/sec

= velocity, ft/sec = gas compressibility factor, dimensionless

= gas compressibility factor, dimensionless

Greek symbols

= absolute roughness, ft

= absolute roughness, ft = viscosity, cp

= viscosity, cp = density, lbm/ft3

= density, lbm/ft3

Subscripts

g = gas

K = °K

L = liquid

R = °R

SG = superficial gas

References

- ↑ Colebrook, C. F. (1938–1939). "Turbulent Flow in Pipes, With Particular Reference to the Transition Region Between the Smooth and Rough Pipe Laws"

. Journal of the Institution of Civil Engineers. London, England. 11: 133–156.

. Journal of the Institution of Civil Engineers. London, England. 11: 133–156.

- ↑ Moody, L. F. (1944). "Friction factors for pipe flow"

. Transactions of the ASME. 66 (8): 671–684.

. Transactions of the ASME. 66 (8): 671–684.

- ↑ Lyons, W.C. (1996). Standard handbook of petroleum and natural gas engineering. 2. Houston, TX: Gulf Professional Publishing. ISBN 0-88415-643-5.